Mold Maintenance

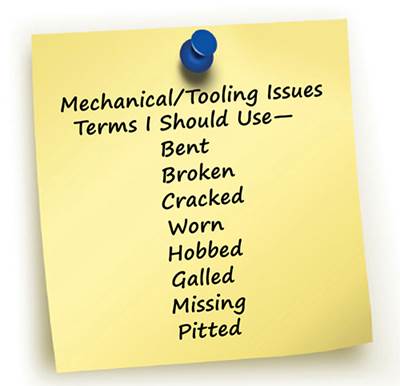

Maintenance Terms of Endearment

Look closely at your company鈥檚 mold maintenance language and formalize your approach to create a clear and concise picture鈥攐ne that can be measured.

Read MoreTOOLING AT NPE: Hot Runners & Coinjection Grab Spotlight

Tooling innovations at NPE focused primarily on multi-cavity closure and medical applications, though there was also a substantial emphasis on large automotive and appliance parts.

Read MoreCures for Common Hot-Runner Wiring Problems

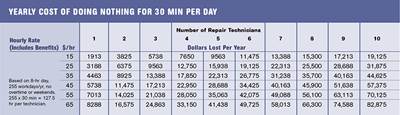

In the challenging environment of the last several years, manufacturers are looking inward to improve their manufacturing processes, streamline their supply chains, lower maintenance costs, andimprove their bottom lines.

Read MoreThe Value of 20 Bits of Data

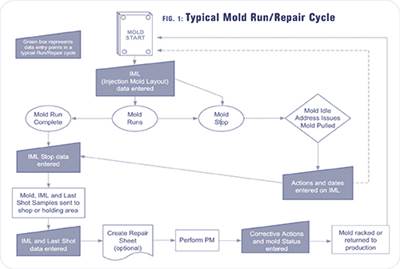

With these 20 bits of data, toolrooms can drastically lower the cost of keeping molds running and improve mold reliability and tooling life while reducing breakdowns and molding better parts.

Read MoreDon’t Just Be a ‘Replacer’

To be a skilled troubleshooter is about understanding how your molds function, paying attention to the details, establishing a consistent troubleshooting method, and using historical data to guide your tooling replacement decisions

Read MoreMold Maintenance Training Eases Molder's Growing Pains

Automation Plastics in Aurora, Ohio (automationplastics.com), is a 32-year-old custom injection molder with 50,500 ft² and 30 presses from 35 to 700 tons.

Read MoreThe Tools of Tool Maintenance

The root cause of many mold and part issues are ultimately determined by the ability to measure something within one or two tenths of a mil. Readings with precision measuring tools can determine whether a tooling component is to be reused, reworked, or scrapped out.

Read MoreCreate a Maintenance Work (Bench) Cell

Get better results by improving the organization of your mold-maintenance operation.

Read MoreTooling: Setting Up Shop: Part III

Our last column covered shop size and bench requirements for a 50 x 50 ft mold-repair shop that will have a MPP (Mold Pull Pace) of approximately 25 to 30 multi-cavity molds a week and employ four repair technicians in a six-bench layout.

Read More