LIM & LSR Molding

Minnesota Rubber and Plastics Opens Innovation Center

The plastics and rubber compounder and molder has opened the 9000-ft2 center that’s intended to help speed product development with design, prototyping, testing and production capabilities.

Read MoreCustom Molder Manages Growth on Several Fronts

Adding people, plants and machines, expanding capabilities in LSR, high-tonnage presses, automation and 3D printing—EVCO Plastics maintains momentum through challenging times.

Read MoreHow a Molder Embraces Change While Sticking to Its Roots

For MDS Manufacturing, its first decade in 大象传媒 has been one of nearly constant change. But the two brothers who started it have never strayed from the company’s roots and the lessons about the molding 大象传媒 they learned from their father.

WatchFakuma: LSR Cells Apply New OPC-UA Compliant EUROMAP Standard for Dosing

Just months after its publication, a EUROMAP standard for interfacing an LSR dosing system with an injection molding was utilized at Fakuma by Arburg and Wittmann Battenfeld.

Read MoreFakuma: New LSR Dosing System and All-Electric Cold Runner

Elmet is introducing the new SMARTmix TOP 7000 Pro dosing system and all-electric SMARTshot E cold runner system at the show in Friedrichshafen.

Read MoreMinnesota Rubber and Plastics to Build Innovation Center

The medical focused injection molder says the new 9000-ft2 innovation center will give its customers a design-prototype-build-test outlet for the creation of new devices and components.

Read MoreFakuma: Boy Brings Eight Machines to Friedrichshafen

Neustadt-Fernthal, Germany based Boy will have four machines at its Fakuma stand this October, with an additional four presses running at partner booths.

Read MoreFakuma: Wittmann Battenfeld to Launch Machine Line at Friedrichshafen Fair

In addition to introducing its new SmartPlus line of servo-hydraulic injection molding machines, Wittmann Battenfeld will feature multiple machines at its booth and stream video of other cells from its labs.

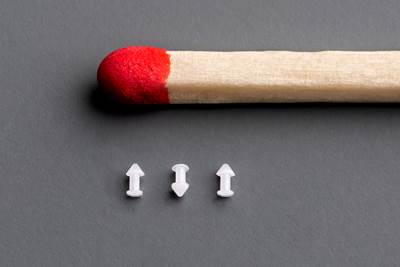

Read MoreMicro-Injection Molding LSR: Exploring the Limits of What’s Possible

Molding delicate LSR parts weighing 0.5 mg in 32 cavities requires high precision and repeatability in molding and careful post-mold handling. Here’s a look at the challenges of micro-molding with LSR and what makes it different from thermoplastic micro-molding.

Read MoreTrelleborg Expands Silicone Molding in Minnesota

Sweden-headquartered Trelleborg has expanded its Delano, Minn. facility, adding clean room silicone molding space.

Read More