Injection Molding

Structural Plastics: Exploring Ways to Make Molds and Parts Faster

New approaches to rapid tooling, rapid prototyping, and gas assist were highlights of the SPI Structural Plastics Conference. It also showed off several eye-opening molded parts.

Read MoreRecycled PET/PE Alloys Show Promise In Monofilament, Pallets, Pipe

Alloys of polyethylene and recycled PET were the highlight of the annual SPE Global Plastics Environmental Conference (GPEC) in Detroit in February.

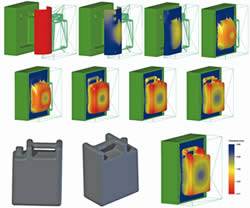

Read MoreBlow Molding Simulation: Ready for Prime Time?

Efforts have been made to simulate the extrusion blow molding process for at least a decade, but actual use has been slow to take hold.

Read MoreLightweight TP Composite Takes the Driver's Seat

A lightweight version of Azdel glass-reinforced polypropylene sheet is gaining ground in a host of new automotive applications.

Read MoreIn-Mold Labeling: Electrostatics Are the Way to Go

Applying a static charge to hold the label in the injection mold eliminates the need for vacuum ports that addsignificantly to the cost of making and maintaining the tool.

Read MoreIn-Mold Lamination: U.S. Auto Market Is Catching Up

Although more widely used in Europe, in-mold laminating is gaining a foothold in U.S. automotive interiors. Molders can choose from a handful of different process technologies that promise labor and other cost savings.

Read MoreAutomotive Innovation Trend-Setting Technologies Garner SPE Awards

Paintless in-mold film decorating and carbon-fiber composites are making inroads in appearance and structural parts. Blow molding is finding new interior applications. And long-fiber thermoplastics are cutting weight and cost on the inside and outside of new passenger vehicles.

Read More'Soft-on-Soft' Is Newest Option In Soft-Touch Molding

It's hailed as a breakthrough for soft-touch injection molding: Collaborative efforts by three companies have resulted in the commercialization of an SEBS-based TPE vehicle handle in which a very soft (28 Shore A) surface layer is coinjected onto a substrate of a firmer—but still soft and rubbery—60 Shore A compound.

Read MoreMicro Molds Make Micro Parts

Molded parts barely visible to the naked eye require non-traditional methods for making high-precision micro-injection molds. Micro-tooling R&D is being led by technology institutes, research firms, and a few highly specialized mold makers.

Read MoreArburg Moves into Mid-Sized Presses And Electric/Hydraulic Hybrids

A move to larger machine sizes and the introduction of an electric/ hydraulic hybrid series were announced recently by injection machine builder Arburg, Inc.

Read More