Injection Molding

Injection Molding: Why & How to Do Gate-Seal Experiments

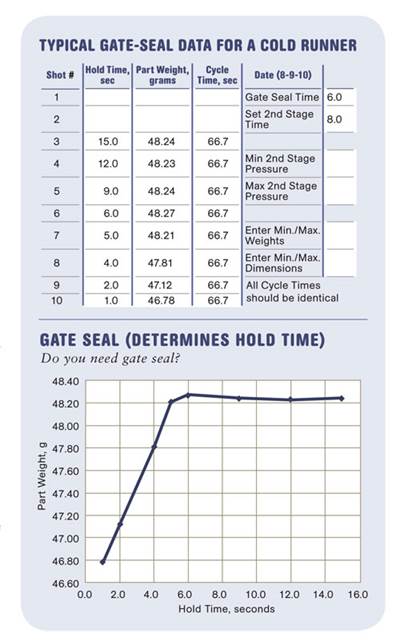

Part of optimizing any molding process is determining the second-stage injection, or pack and hold, parameters.

Read MoreCompressed Air Isn’t Free!

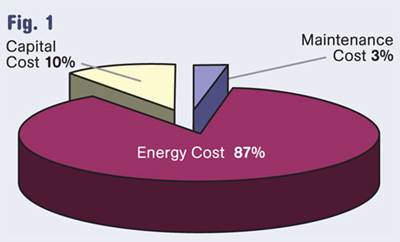

Compressed air is a convenient and often essential utility, but it is very expensive to produce, and most of the energy used to compress air is turned into heat and then lost to the system and environment.

Read MoreK 2010 Preview, Auxiliaries: Equipment of All Types Debuts This Month at K 2010

From materials drying, feeding, and blending to process heating/cooling, scrap reclaiming, testing, welding, and decorating—the K 2010 show this month in Dusseldorf, Germany, will have news in all categories of auxiliary equipment.

Read MoreTips and Techniques: How to Get Best Results With Insert Fasteners

The weakest sections of many plastic part designs are the joints and assembly points.

Read MoreLargest Aluminum Injection Mold Ever

Unique Tool & Gauge, Windsor, Ont. (unique-tool.com), completed a production injection mold machined from the largest block of tooling-grade aluminum ever forged.

Read MoreGeothermal Cooling Works in Molding, Too

While geothermal water-cooling systems are becoming known as an energy-saving alternative for residential use, they are still quite novel in plastics processing.

Read MoreAutomation, Old-Fashioned Values Help Sustain Molder’s Success

This 55-year-old, family-owned and operated custom injection molding company continues to thrive by practicing a value that’s gained widespread popularity lately: “sustainability.”

Read MoreInjection Molding: Answers to Bozzelli's Drying Quiz

Three questions about drying plastics that everyone should know how to answer.

Read MoreOn-Site: This Currier Delivers

“We love to tell our story.” That’s one way Mike Cartner, CFO of Currier Plastics, defines what separates this family-owned custom processor from its competitors.

Read MoreINJECTION MOLDING: Automation and Integration At K Show

There were new presses of all stripes aplenty at K 2010, but the “wow” factor was supplied by automated work cells and integrated manu-facturing systems performing multiple operations before, during, and after molding.

Read More