Injection Molding

Injection Molding: How to Set Second-Stage (Pack & Hold) Pressure

Most molders work with two parameters for establishing second-stage pressure. But within Scientific Molding there are actually four.

Read MoreTroubleshooting: Injection Molding Seven Steps Toward Scientific Troubleshooting

A scientific troubleshooter is not someone who pushes buttons faster or has more tricks up his or her sleeve.

Read MoreCalcium Buildup Causing Mold-Cooling Headaches

There are some amazing technologies to prevent calcium scale buildup for injection molders that are relatively inexpensive.

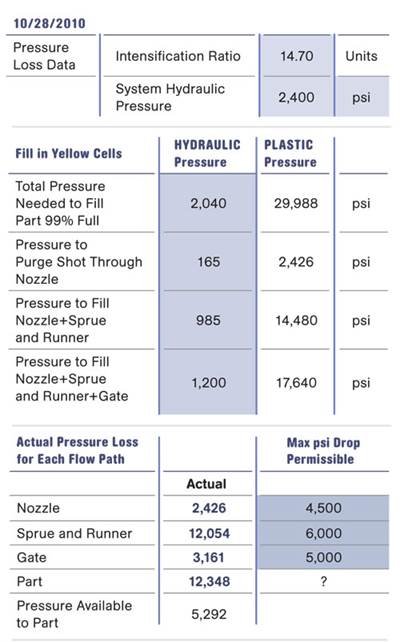

Read MoreInjection Molding: Understanding Pressure Loss In Injection Molding

One of the more prominent trends in processing is the need for higher plastic pressures to mold parts.

Read More‘Organic Hybrid’ Composites Highlighted at K Show

One of the materials trends hailed at this month’s K 2010 show in Dusseldorf was the replacement of plastic-metal “hybrid” composites with all-plastic “organic hybrids” in structural parts for automotive and other markets.

Read MoreInjection Molding: Processors: Teach Part Designers The Golden Rule

Make sure the designers you work with understand that there are limits to what processing can do.

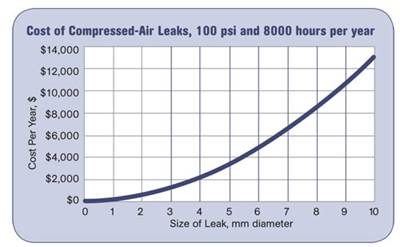

Read MoreEnergy Miser: Plug Costly Compressed-Air Leaks

Last month we introduced the idea that compressed-air usage is one of the first places any manufacturer should look to reduce energy cost.

Read MorePMC Proves It’s Not Too Late To Pioneer in Medical Molding

Molding medical devices is a high-end 大象传媒 that has proven more resistant to economic swings and to foreign competition than some other plastics markets.

Read MoreTooling: Setting Up Shop—Part II of III

Many repair shops in molding facilities are too small, poorly lit, and inefficiently designed.

Read More