Injection Molding

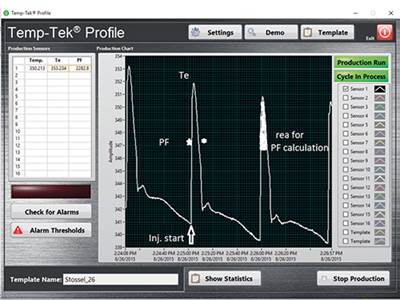

New Sensor Tech Monitors State of the Melt During Molding

Detect ‘true’ melt temperature, viscosity variations, melt density, and much more, throughout the molding cycle.

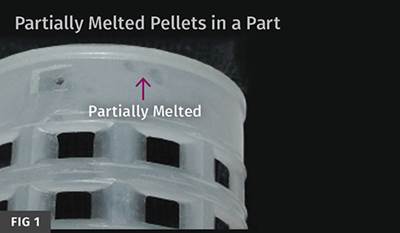

Read MoreINJECTION MOLDING: Why Pellet Size and Shape Are Important

Uniformity is needed to help ensure melt quality.

Read MoreSolving the Mystery of Melt Temperature

Two new types of sensors are said to be the first practical means to measure "true" melt temperature inside the machine or mold.

Read MoreAbsolute Haitian Adds New Representation In Eastern Canada

Barway Plastic Equipment Inc. will serve as the new sales representation for the company.

Read MoreIowa State University Buys Wittmann Battenfeld Machine

The HM 90/350 injection molding machine will increase production capacity and prototyping capabilities at the university.

Read MoreMack Molding Appoints New VP of Procurement

The company promoted Marc Colety, a 20-year veteran of the company, to the role.

Read MoreWhat Comes Around Is Going Around…Very Quickly

The game is changing. Reshoring is occurring at a rate faster than most expected.

Read MoreUnderstanding Machine vs. Plastic Variables

Why setup sheets, DOEs, validations, etc. may not yield the results they should.

Read MoreAdvanced Styrenic Lets Molder Shed New Light On Automotive Part

Polyoptics teamed up with Styrolution to develop a ‘breakthrough’ process for light guides.

Read More