Injection Molding

Hot/Cold Injection Molding: Which Approach Is Best for You?

The hot-and-cold molding process gives molders a new tool to achieve top-quality esthetics or to fill challenging thin-wall parts. There are a number of options in heating methods, and this article discusses the ins and outs of each.

Read MoreHigh-Tech Molder Modernizes Its Fleet

EPC replaces older presses with its first all-electrics, in integrated cells from a single source.

Read MoreMOLDING 2016: New Approaches to Processing, Tooling & QA

The largest-ever annual Molding Conference included newsworthy technical presentations on a variety of injection molding topics. Here’s a selection.

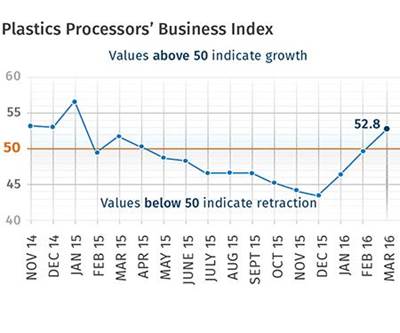

Read MoreMarch 2016 Index: 52.8

Processing 大象传媒 index registers growth for first time in 10 months.

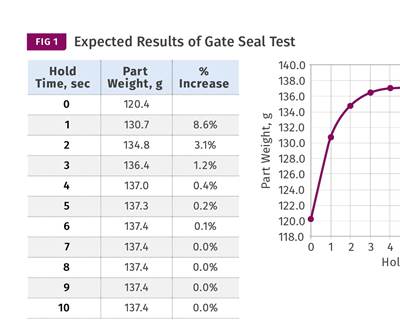

Read MoreINJECTION MOLDING: Gate Freeze Study: Danger in a Name?

The test actually determines the hold time needed to mold repeatable parts, and it should be done regardless of whether the gate freezes or not.

Read MoreColor Done Right

Look for a supplement to the September Issue of Plastics Technology with tips and techniques that will help you make your coloring operations as efficient as possible

Read MoreAdvanTech Hopes To Open Up New Closure Market

A linerless, one-piece injection molded cap for carbonated soft drinks cuts weight dramatically.

Read MoreMacro Plastics Adds Two New Negri Bossi Bi-Power Machines

Installation of the new Bi-Power presses and Sytrama robots was completed in March 2016.

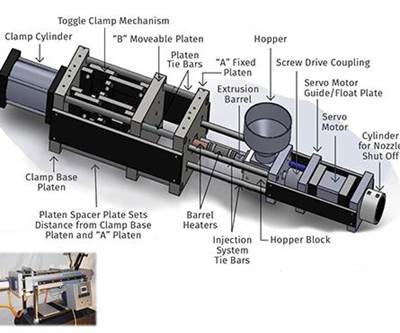

Read MoreNew Injection Screw Is Said to Be Truly ‘All-Purpose’

A mixing section with removable dams can adjust melting capability to the viscosity of the material.

Read MoreIntroducing 'HD Plastics'

"High Definition Plastics" is a new way of thinking about the benefits of heat/cool molding with induction heating.

Read More