Injection Molding

Injection Molding: Work Stations Promote Lean Operations

Customized workflow stations help keep injection molders' plant floors organized.

Read MoreTessy to Expand Upstate New York Facility

The injection molding contract manufacturer will invest $20 million to expand its South Plant in Elbridge by 100,000 ft2.

Read MorePaul Caprio Joins Engel North America

Formerly head of KraussMaffei's North American operations, Caprio will serve as president alongside Engel CEO Mark Sankovitch.

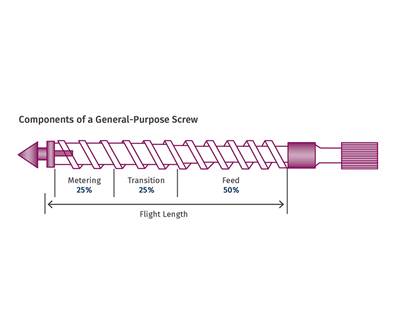

Read MoreRevisiting Shot Size vs. Barrel Capacity

We’ve covered this topic before, but it’s important enough to warrant another look..

Read MoreSave Time, Money: Use a Mold-Design Checklist

Here are 15 examples of common molding issues that occur during an initial mold trial. Many of them could be avoided or corrected with a proactive checklist.

Read MoreTenere Shapes Market Niche Where Metal and Plastics Meet

Joining metal and plastics to target some of today’s most dynamic industries, contract manufacturer Tenere reinvented itself—and its customer list—in 2016.

Read MoreInjection Molding: Faster, Smarter, More Efficient Machines Tackle Sustainable Molding at K 2019

Blazing speed plus shrinking energy consumption supported the “green” theme at the big show. Smarter controls and growing connectivity were another key focus.

Read MoreMicromolder Makuta Adopts Carbon 3D Printing

Special printing process opens up new 大象传媒 for custom injection molder in functional prototypes and short runs of complex parts.

Read MoreYizumi-HPM Introduces Molding Auxiliaries

Yizumi-HPM will be able to supply complete molding cells.

Read MoreSimulation Is Making Injection Machines Smarter

Engel’s simlink will refine offline simulation with results from actual molding and use Engel’s machine data to constrain simulation within the actual machine’s capabilities.

Read More