Extrusion

Enterprise Software Solution Smooths Custom Extruder’s Growth

Sometimes an operation can grow too quickly, even beyond its ability to manage the new 大象传媒. Custom Profile solved this problem by replacing off-the-shelf and home-made enterprise software with one comprehensive package.

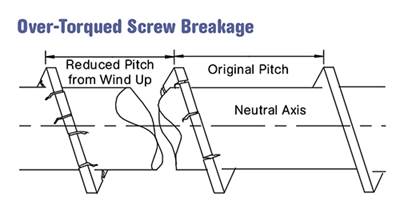

Read MoreUnderstanding Screw Breakage

You might think you're over-torquing the screw, but more often than not bending is the reason.

Read MoreReifenhauser to Unwrap New Extruder, Other Innovations

New machine and novel approaches in blown/cast film, sheet, and wood composites touted.

Read MoreCalibrate Those Instruments

Make sure that your instruments are calibrated on a regular bases and also do a check and balance when gathering data. Never trust what you think you see the first time.

Read MoreIML Groundbreaker Adds Sheet Extrusion

In-house sheet production allows Tech II to vertically integrate to hasten product development, control costs.

Read MoreBD’s Holistic Approach To Sustainability

For medical device giant Becton Dickinson, sustainability takes into account material selection, manufacturing, packaging, logistics, waste reduction, energy use and reduction, and more.

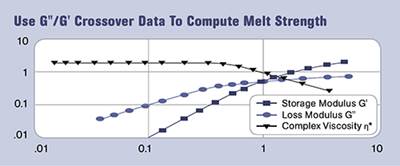

Read MoreExtrusion: Where's the Data? The Importance of Melt Strength in Extrusion

All extrusion processes depend to some degree on the melt strength of the polymer, and this property is generally a no-show on data sheets.

Read MoreCompostable Drinking Straws from PLA

WEB EXCLUSIVE: A proprietary PLA-based bioplastic from Cereplast, Inc., El Segundo, Calif., is being used in new compostable drinking straws sold under the Cello-Green Bio Straws brand by Cell-O-Core Co., Wadsworth, Ohio.

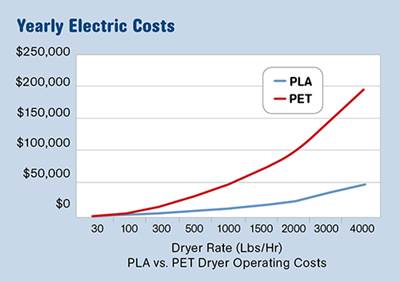

Read MoreConveying, Drying, Crystallizing PLA : The Energy-Saving Packaging Solution

When the new industry term “bioresins” hit the plastics community in the early 2000s, polylactic acid (PLA ) made its way to the top of the list in a class of new plant-based materials.

Read MoreNew Supplier of Pipe Extrusion Equipment

There’s a new company supplying complete extrusion systems for solid-wall pipe production.

Read More