End Markets

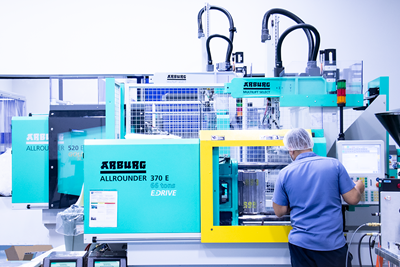

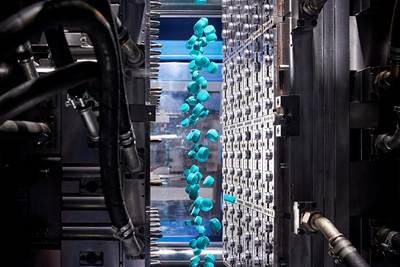

Natech Adds Injection Molding, Automation Equipment

Two new Arburg presses and four filling and sealing lines have been installed in the molder’s Class 8 cleanroom in support of medical diagnostics, including COVID-19 testing.

Read MoreHayco Molding Plant Garners LEED Platinum Certificate with Assist from Wittmann Battenfeld

82 servo-hydraulic injection molding machines help Hayco’s plant in the Dominican Republic win environmental award from the U.S. Green Building Council.

Read MoreAnti-Stat Compounds for Explosive Environments

SABIC’s new materials meet EU’s ATEX safety requirements for electrical conductivity while giving customers a choice of desirable performance and processing attributes.

Read MoreChemically Recycled EPS Packaging Used by High-End Design Furniture Maker

BASF’s Styropor Ccycled used by Ekornes for its Stressless furniture brand.

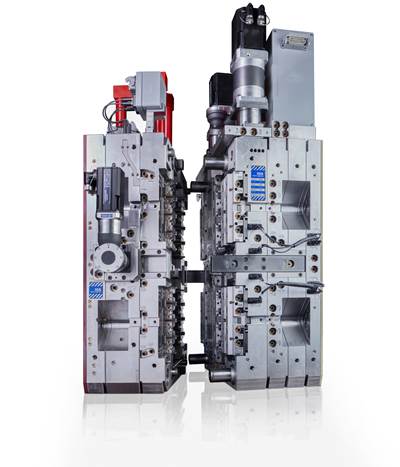

Read MoreEuropean Moldmaker Launches U.S. Subsidiary

Dutch firm IGS GeboJagema’s North American division will be based in Washington D.C. and initially focus on sales and service support to its existing client base.

Read More100% Biobased PET Bottle Gets Closer to Commercialization

It’s not here quite yet, but ability to make both key PET precursor chemicals from plant-based sources is “ready for commercial scaling.”

Read MoreEcoCore PP-Based Recyclable and Reusable ‘Zero-Waste’ Cups Used At COP26

Bockatech’s EcoCor foam core technology for lightweight and reusable packaging ‘starred’ at this year’s conference.

Read MoreThe Accidental Molder

Peyton Owen came to plastics after decades in commercial real estate, but by empowering his employees through listening, he’s learning molding and success at D&M Plastics.

Read MoreALPLA to Add Facility in Missouri

The 246,000-ft2 greenfield site in Kansas City will be dedicated to injection molding and completed in late 2022, with groundbreaking slated for later this year.

Read MoreBuilding a Better Bottle

To ensure successful package development, all stakeholders must come together at the start of the project to establish the goals, functional requirements and desired outcomes for each new bottle design—as well as identify any limitations or complex challenges associated with fulfilling those goals.

Read More