Natech Adds Injection Molding, Automation Equipment

Two new Arburg presses and four filling and sealing lines have been installed in the molder’s Class 8 cleanroom in support of medical diagnostics, including COVID-19 testing.

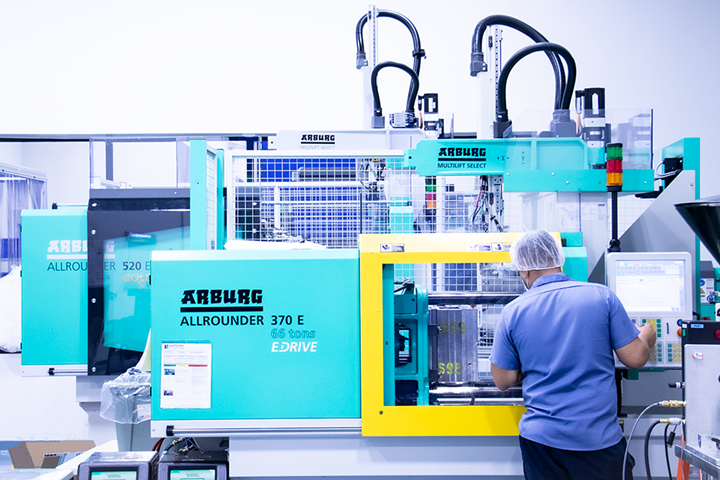

Natech Plastics (Ronkonkoma, N.Y.) has installed six new pieces of equipment in the fourth quarter of 2021, including two Arburg injection molding machines and four custom-made filling and sealing machines. A Natech spokesperson said the latest machines come with clamp forces of 110 and 165 tons, respectively. Natech’s machine fleet of 16 presses ranges in size from 40 to 400 tons.

Natech’s facility includes an ISO Class 8 Cleanroom and engineering and design services, as well as secondary operations. The two new injection molding machines, alongside the cleanroom, will be used to manufacture medical and diagnostics products, including molded plastic components and finished devices. In particular, the spokesperson said Natech is expanding its support of diagnostics industry, including a program focused on COVID-19 testing, with these machines supplying filled tubes and bottles for rapid antigen tests.

The four new filling and sealing machines added to the cleanroom space were custom-designed and built for Natech. Featuring a modular, interchangeable design that allows for a variety of processes (filling, capping, heat sealing) to run on a single machine, they also have a built-in shuttle so filled product can be transferred to the sealing station. The rapid COVID-19 antigen tests require filling and and sealing of containers that house extraction buffers. Natech noted that the new Arburg machines allow the machine, conveyor and robot to all be integrated.

Natech has added two Arburg injection molding machines to its fleet in support of medical diagnostics products, including COVID-19 rapid antigen tests. (Photo: Natech)

Related Content

-

Navigating Medical Plastics Trends in 2025

The past few years have tested the resilience of the health care supply chain, especially when it comes to medical plastics.

-

Arterex Acquires Italian Medical Device Provider

Arterex’s acquisition of Phoenix S.r.l. continues its growth mission to offer customers in North America and Europe diversified, high-precision medical device manufacturing solutions.

-

Krones Acquires Netstal

Krones adds PET preform injection molding to its bottle blowing and filling capabilities, as well as cap molding and expansion into medical, food and other markets.