dies

Italian Machine Builder GAP Installs 27-Layer Blown Film Line

System consists of nine extruders feeding 400-mm annular die, an automatic gauge-controlling air ring, and other features.

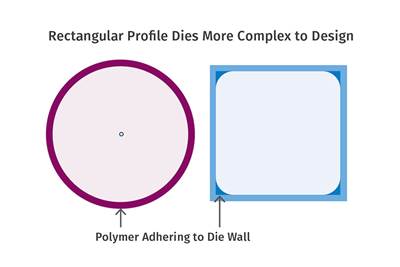

Read MoreExtrusion: Follow These Tips to Get Profile Die Design Just Right

Calculating polymer flow is fairly straightforward when designing a die for a simple round profile, but as the shapes get more complicated these calculations can get extremely challenging. Here’s what you need to consider.

Read MoreNew Die-Cleaning System Boosts Efficiency for Film Processor

IPG’s investment in Schwing’s cleaning system impacts processor’s bottom line by getting dirty film dies back in production quickly.

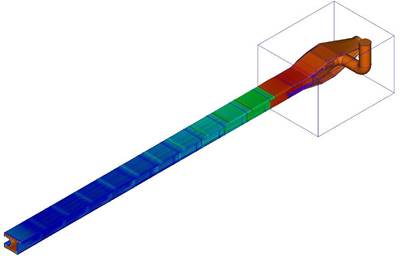

Read MoreProfile Die Design Software Simulates Cooling, Shrinkage

Enables use up of to 20 calibrators in the cooling system.

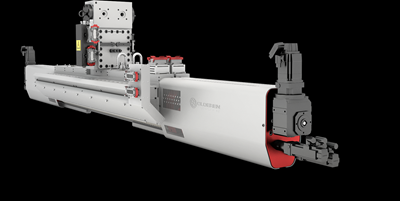

Read More‘Game Changing’ Flat Die Lives Up to Its Billing

Revolutionary ‘touchless’ die and control system for cast film and coating/laminating offer speed, efficiency and operational efficiencies to processors that were previously ‘unheard of.’

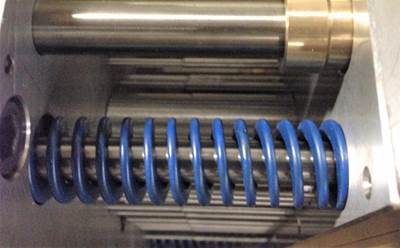

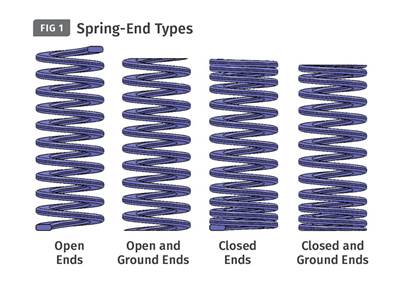

Read MoreTooling: Back to Basics On Die Springs--Part 2

Follow these steps for proper die-spring selection and installation.

Read MoreTooling: Back to Basics on Die Springs Part 1

Some molding shops insist that all of their molds have springs to return the ejector plates. And there are lots from which to choose. Here we’ll focus on compression die springs for injection molds.

Read MoreNew Mold Grease Smooths Operations for Troublesome Tool

Switching to a new synthetic grease helped an injection molder keep a difficult die running, eliminating unplanned downtime and cutting scrap.

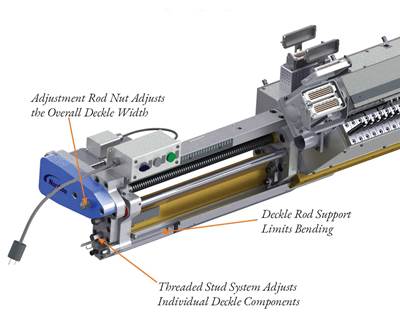

Read MoreExtrusion: Auto Die for Coating Applications

Equipped with a motorized internal and external deckling system for safe and easy operation.

Read MoreExtrusion: Enhanced Deckle Boosts Coating Productivity

Simplified mechanisms for Nordson EPC die streamline the adjustment of coating width while reducing the size of edge bead.

Read More