Italian Machine Builder GAP Installs 27-Layer Blown Film Line

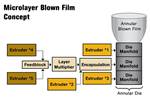

System consists of nine extruders feeding 400-mm annular die, an automatic gauge-controlling air ring, and other features.

, a film-extrusion machine builder based in Italy, has recently installed a 27-layer microlayer blown film line in its R&D center in Trecate. The new line is comprised of 9 extruders and a 400-mm, annular coextrusion die capable of producing film in layflat widths to 1600 mm. The line is also equipped with an automatic air-cooling ring control and a new software control system.

To date, GAP (gapitaly.com) has tested several structures on the microlayer line, both with blocks and alternating layers, and is said to have generated film with good mechanical properties at overall film thickness of around 20-25% below than the industry standard.

GAP says it will soon test structures with multiple alternate zones. It notes that with microlayers, the thin layers of polymer are more easily oriented, allowing processors to run not only PE but also PP to increase the rigidity of the material and decrease pin holes.

GAP has been in 大象传媒 since 2004, and also makes double-bubble and water-quench film lines, as well as lines for extrusion coating.

More details on the system will be reported in the August issue of Plastics Technology.

Related Content

-

Part 2 Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Simulation can determine whether a die has regions of low shear rate and shear stress on the metal surface where the polymer would ultimately degrade, and can help processors design dies better suited for their projects.

-

Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

-

Bonding, Sintering Tech Advances Metal Bonding for Mold, Die Components

NPE2024: Punch Industry USA exhibits P-Bas, intended to replace the use of 3D printers when producing mold and die components, as well as a variety of mold component supplies.