dies

Screw, Barrel Innovator Paul Colby Dies

Entrepreneur who built Spirex into a leading producer of screws and barrels was inducted into the Plastics Hall of Fame in 2009.

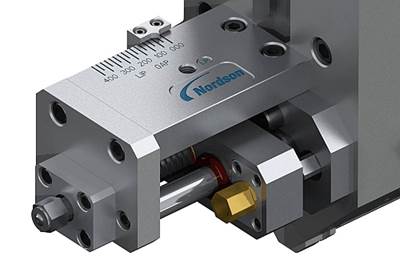

Read More‘Breakthrough’ Tech Allows for Fast Sheet-Thickness Changes

New system uses a single-point adjustment to change the lip gap and modify the lip land length at the same time.

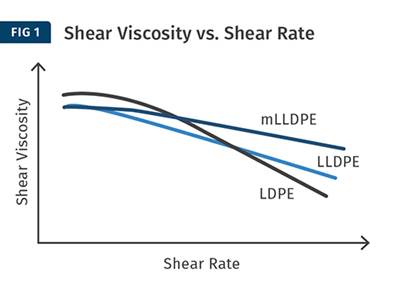

Read MoreCoextruding Blown Film Needs Deeper Understanding of Resin Rheology & Die Design

More film processors are investing in lines with nine or more layers. With more resin possibilities and combinations coming into play, it’s important to learn more about material rheology and compatibility, as well as die design.

Read MoreMachinery Innovator Dewey Rainville Dies at 91

Developed numerous technologies in blow molding; involved in start-ups of leading auxiliary equipment firms.

Read MoreHow to Split & Clean Flat Dies

Notice a drop-off in quality of your flat film or sheet? It may signal that a die ‘split-and-clean’ is due. Here’s how to get going.

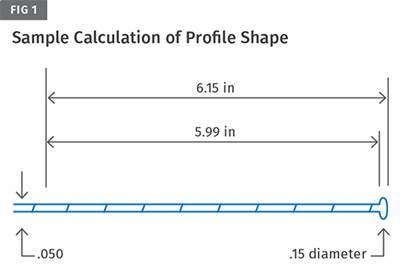

WatchEXTRUSION: About Your ‘General-Purpose’ Dies

There is no such thing. While dies can be adjusted to provide some flexibility, the fact is they are optimized for one specific output of one particular polymer.

Read MorePelletron Founder Jerry Paulson Dies

Developed de-dusting technology that is still considered industry standard.

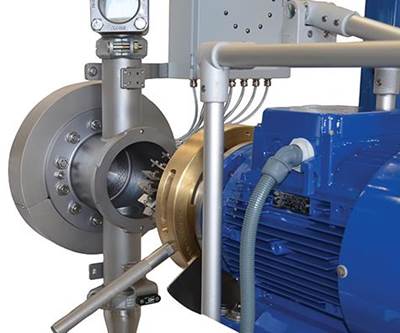

Read MoreSolving Common Problems in Underwater Pelletizing

Pellet quality and consistency are critical to any compounding operation. But in underwater pelletizing, a variety of issues can stand in the way. Here’s how to fix them.

Read MoreChem-Pak Founder 'Pete' Duane Dies

Developed a range of coating products still in widespread use today.

Read More