iMFLUX Inc.

3550 Symmes Rd.

Hamilton, OH 45015 US

513-360-4448

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

iMFLUX Inc. Supplies the Following Products

- Pressure Controllers, Monitors

- Prototyping Services

Editorial, News, and Products

-

RJG Adds iMFLUX Technology to Injection Molding Offerings

RJG Inc. will supply and support iMFLUX’s pre-engineering, installation and service for all hardware and software components.

-

NPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

-

iMFLUX Goes Royalty-Free and Transitions to Mainly R&D Role

By July, P&G will close the iMFLUX site and move to royalty-free licensing through injection-machine vendors and third-party retrofitters. An iMFLUX R&D team will continue to develop the technology.

-

Machine Intelligence Mobilized Against Waste

Part quality was naturally the first target of autonomous molding algorithms, but later developments have focused increasingly on preventing wasted time, energy, material and hardware maintenance.

-

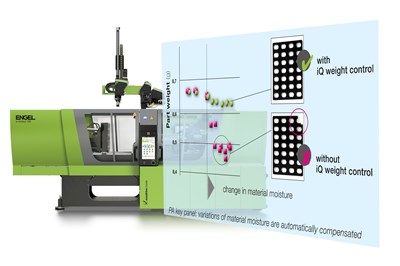

The Secret to Molding with PCR: Don’t Fear Variation – Embrace It!

“Embrace variation” – That contradicts all normal thinking about processing plastics. But the only thing that’s “normal” about recycled plastics is variability, and that requires a processing philosophy that assumes variation and is geared to deal with it.

-

What is Backpressure and How Should We Calculate It?

Does using an intensification ratio to calculate backpressure result in an accurate reflection of what’s happening in the barrel? Newer machine technologies have us revisiting an old project with fresh eyes.

-

‘Learn to Embrace Variability’

Wait. What? Variability in raw materials is supposed to be the last thing anyone would want to ‘embrace.’ But if you substitute ‘circular economy’ for ‘variability’ and ‘manage with technology’ for ‘embrace’—then the mystery starts to clear.

-

Injection Molding Live Demos to Highlight First-Ever PTXPO

Major suppliers will be running injection machines in the first plastics industry trade show in the Chicago area since 2009.

-

JSW and iMFLUX Announce Partnership

The collaboration agreement would integrate iMFLUX processing software on the full line of JSW America presses.

-

iMFLUX Plots Path to Autonomous Molding

iMFLUX used a virtual event in May to lay out a path to autonomous molding where “the machine is making intelligent decisions on behalf of the operator.”

-

Absolute Haitian and iMFLUX Partner

The distributor of Haitian injection molding machines in the U.S. and Canada has partnered with the P&G subsidiary to bring iMFLUX’s low constant-pressure molding platform to the market.

-

20 Good Things to Come Out of 2020—Part 4

Good news was there if you knew where to look for it—in the pages of Plastics Technology magazine or right here on our website. Here’s a review of headlines you can feel good about.

-

JSW America Opens New Offices, Tech Center & Large-Machine Assembly Plant

Regional offices in the West and Midwest have moved to more accessible locations; new Tech Center and assembly plant opens in New Jersey.

-

Low-Pressure Injection Process Facilitates ‘Green Molding’

Besides speed and quality advantages, the low-pressure iMFLUX process is said to enhance sustainability—easing use of recycled and biobased materials, saving energy, reducing scrap, and adding lightweighting potential. See what molders say about these “green” benefits.

-

Penn State Behrend Installs Consigned Zeres Injection Molding Machine

The university’s plastics processing lab will use the electric 101-ton Zhafir Zeres injection molding machine in hands-on coursework as part of its B.S. in Plastics Engineering Technology.

-

iMFLUX Leverages Its Resources to Fight Coronavirus

P&G’s subsidiary pressed its design and moldmaking expertise into service to make face shields and nasal test swabs for the COVID-19 pandemic.

-

Recycled Resin Gains Molder a Green Niche

Injection molder AGS Technology uses compounding know-how to turn old scrap into new auto parts that satisfy performance and sustainability goals.

-

Wittmann Battenfeld Deploys iMFLUX Low Constant Pressure Molding at Plastec West

A Wittmann Battenfeld SmartPower 110 machine will be molding a 4-cavity dosing cup using iMFLUX technology in Anaheim at the show (Feb. 11-13).

-

Injection Molding: Faster, Smarter, More Efficient Machines Tackle Sustainable Molding at K 2019

Blazing speed plus shrinking energy consumption supported the “green” theme at the big show. Smarter controls and growing connectivity were another key focus.

-

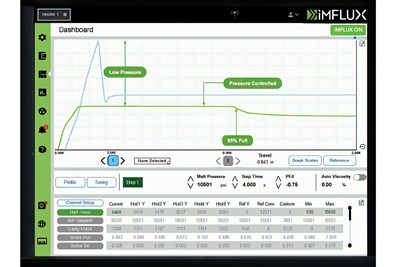

Moving Toward ‘Autonomous Molding’ with a Uniform-Low-Pressure Process

A new low-pressure injection molding process has aroused interest among molders and machine suppliers. In his second article on iMFLUX, the inventor of the process explains how it is evolving to support the overall industry goal of self-correcting molding processes that can compensate for common causes of variation to maintain consistent part quality.

-

How to Mold This ‘Impossible’ Part

New low-pressure injection molding process “breaks the rules” and solves difficult molding problems.

-

K 2019 Preview: Injection Molding Goes for the ‘Green’

‘Circular Economy’ joins Industry 4.0 as common themes of injection molding exhibits in Düsseldorf.

-

New Process Eliminates Resin Variations as a Quality Variable

At Molding 2019, learn about the latest enhancements to the iMFLUX low-pressure injection molding process, including Auto Viscosity Adjust to compensate for resin variations.

-

Full Plate of New Technologies on the Table at EVCO Plastics

A new low-pressure molding process, 3D printing of production parts and prototype tooling, collaborative robots, and process monitoring with automatic QC are all on the menu.

-

Headlines from Fakuma 2018

Integrating a special low-pressure process into machine controls; novel shop-floor quality-inspection technology; MES systems from machine and controls vendors; and sophisticated in-mold decorating.

-

Milacron Is First to Integrate iMFLUX into Machine Controller

Integrating iMFLUX low-pressure process into machine controls is a more economical route to faster cycles and improved part quality.

-

Milacron Demonstrates iMFLUX Low-Pressure Injection Molding at Fakuma Show

Milacron is first to demonstrate this innovative low-pressure process at a trade show.

-

A New Way to Mold Better Parts Faster and Easier

A new injection molding process ‘breaks all the rules’ by using low, constant pressure to achieve faster cycles and better-quality parts.