Materials: New PAEK Filament Optimized for Additive Manufacturing

Chinese 3D printing manufacturer INTAMSYS becomes the first reseller of Victrex’s new AM PAEK for 3D printing.

Victrex has launched the new Victrex AM 200 filament, which been specifically developed and optimized for additive manufacturing (AM).

The company says that the stand-out mechanical properties of PAEK are in demand for high performance parts. However, according to Victrex, they were difficult to be fully realized in 3D printed parts with existing choices such as PEEK and PEKK. For example, the company claims that repurposing injection molding PEEK into filament fusion AM, typically results in weak parts because of poor interlayer bonding. This new material is designed to address this weakness in printing PEEK.

The first 3D printing equipment supplier to offer Victrex’s new AM PAEK filament is INTAMSYS, China, a company that provides high-performance 3D printing materials, direct additive manufacturing solutions and software.

INTAMSYS has conducted physical and mechanical performance tests on the new Victrex PAEK filament material.

According to INTAMSYS’ experience using its manufacturing equipment, the Victrex AM 200 filament has a higher Z-axis strength and has shown to date up to 80% strength in the XY direction with a better fused filament forming (FFF) printing adaptability than the existing PAEK materials.

Victrex’s new PAEK AM filament has been developed to support a variety of demanding applications because of its very high wear resistance, high temperature resistance, fatigue resistance, and corrosion resistance to fluids/chemicals.

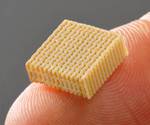

Parts printed with Victrex AM 200 filament.

Related Content

-

420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's additive manufacturing technology is designed for precision tooling.

-

Make Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

-

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.