Fakuma 2023: Oerlikon HRSflow Showcases Sustainability-Focused Technologies

Packaging and automotive applications highlighted via stack mold, hot runner nozzle and valve-gate technologies.

Oerlikon HRSflow (booth 1216, hall A1) will display it’s previously introduced stack mold technology for efficient molding of thin-walled, ecologically optimized packaging. Patent-pending and available soon, the system features the new Xd series nozzles, enabling high filling pressures. The stack-mold design allows a lower tonnage press to be used and Oerlikon HRSflow says they system is suited for processing PCR plastics and sustainable compounds.

In addition, Oerlikon HRSflow will show a 72-cavity cap molding system utilizing its Vf nozzle series, which reportedly enables cycle times of 2.2 to 3.5 seconds and balanced fill. The design satisfies new Europes single-use plastic directive, which mandates tethered closures for all beverage containers up to three liters in volume.

Specially developed for HDPE caps and closures, the Vf nozzles can fill part weights from 0.5g to 8g. The design features a special nozzle tip that enables optimum control in the gate area while improving cycle time. Replaceable nozzle tips ease maintenance, and Oerlikon HRSflow says the hot runner geometries have been rheologically optimized. In addition, special inserts minimize color-change times.

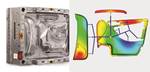

FLEXflow technology will also be presented at Fakuma 2023. The servo-driven valve gate system is combined with a programmable control, allowing independent adjustment of the stroke and force of the needle position of each individual nozzle during the opening and closing phases for cascading injection processes.

Oerlikon HRSflow will put sustainability in focus at Fakuma 2023.

Photo Credit: Oerlikon HRSflow

Related Content

-

What You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

-

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

-

Scaling New Heights With Vertical Integration

Eden Manufacturing was founded on a vision of vertical integration, adding advanced injection molding capabilities to a base of precision moldmaking and more recently bringing Swiss-type machining capabilities in-house.