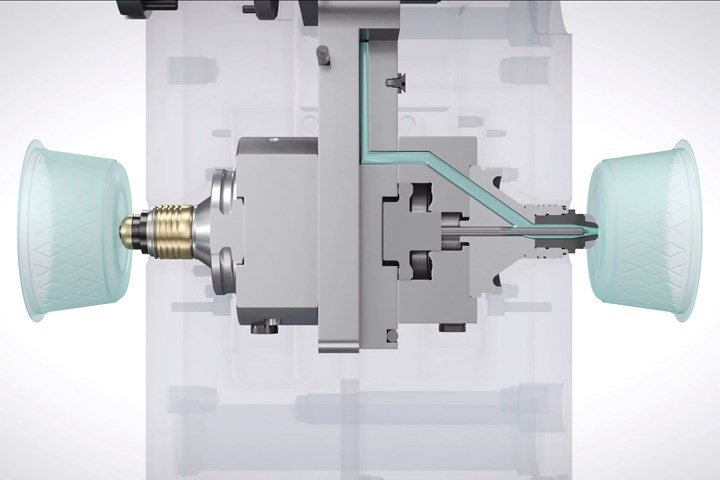

Compact Stack Mold for Thin-Wall Packaging

Oerlikon HRSflow says the patent-pending design allows the use of smaller injection molding machines while still promising the high output a stack mold tool.

Hot runner manufacturer Oerlikon HRSflow has designed a patent-pending compact stack mold for thin wall packaging applications. Designed to withstand high filling pressures for thin wall packaging applications, the system, which will be available soon, can be run on lower tonnage injection molding machines and is equipped with the company’s Xd nozzle series.

The design fits a maximum hot half plate thickness of 220 mm with a minimum distance between the gates on either side of the plate of 260 mm. In a video released with the announcement, Oerlikon HRSflow showed a four-drop design molding two 210-ml single-serving cups in recycled PP with a weight of 6.3g and a wall thickness of 0.3 mm on either side of the middle plate. What Oerlikon HRSflow calls a “mosaic” design on the cups’ walls was patented by moldmaker Collomb and imparts robustness to the container despite the thin walls.

The center plate of Oerlikon HRSflow’s stack mold fits a maximum hot-half plate thickness of 220 mm.

Photo Credit: Oerlikon HRSflow

Related Content

-

Flexible-Film Processor Optimizes All-PE Food Packaging

Tobe Packaging’s breakthrough was to create its Ecolefin PE multilayer film that could be applied with a specialized barrier coating.

-

Coca-Cola’s Redesign of Small PET Bottles Pushes Lightweighting Below Prior ‘Floor’

Coca-Cola thought it had reached the limits of lightweighting for its small PET carbonated soft drink bottles. But a “complete redesign” led to a further 12% reduction.

-

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.