Enhanced Hot Runner Manifold Leak Detection

The Advanced Plastic Leak Detection capabilities on Mold-Masters’ TempMaster hot runner temperature controllers now include thermal identification via thermocouples.

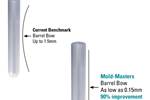

Mold-Masters announced an enhancement to the Advanced Plastic Leak Detection capabilities on its TempMaster hot runner temperature controllers, adding thermal analysis to detect plastic leakage within the manifold pocket.

To enable this feature, thermocouples are installed on the manifold in various locations. These sensors are dedicated to monitoring and detecting manifold leakage. The size of the manifold will dictate how many detection thermocouples are necessary, and the position of each thermocouple will determine how quickly leakage is detected. Mold-Masters says that during internal testing of the new feature, leakages were discovered before any damage had occurred.

Manifold Leakage Detection is an optional feature available now with all Mold-Masters TempMaster M2+ and M3 hot runner temperature controllers. The company’s original Plastic Leak Detection feature, which detects plastic leakage within the nozzle pocket, is included with all M2+ and M3 controllers as standard.

The Advanced Leak Detection package for Mold-Masters’ TempMaster hot runner temperature controls thermally identifies leaks.

Photo Credit: Mold-Masters

Related Content

-

Hasco Marks a Century in Mold Components, Mold Bases and Hot Runners with Cake and New Technologies

NPE2024: Cake, drinks and the unveiling of a new North American website providing online ordering in the U.S. and Canada for the first time are just some of the things happening at Hasco’s booth as it brings its year-long centennial celebration to Orlando.

-

End Ring Valve Gate Optimizes Multicavity Application Injection Molding

The EYEgate HRS features a specially designed pin guide system engineered to ensure permanent pin-gate alignment to significantly enhance the end ring’s durability.

-

How to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.