.jpg;maxWidth=250;quality=70)

Michael Sepe Independent Consultant

Fundamentals of Polyethylene – Part 3: Field Failures

Polyethylene parts can fail when an inappropriate density is selected. Let’s look at some examples and examine what happened and why.

Read MoreThe Fundamentals of Polyethylene – Part 2: Density and Molecular Weight

PE properties can be adjusted either by changing the molecular weight or by altering the density. While this increases the possible combinations of properties, it also requires that the specification for the material be precise.

Read MoreThe Fundamentals of Polyethylene – Part 1: The Basics

You would think we’d know all there is to know about a material that was commercialized 80 years ago. Not so for polyethylene. Let’s start by brushing up on the basics.

Read MorePART 2: The Importance of Mold Temperature When Processing Polycarbonate

Don’t be afraid to increase mold temperature to improve part quality when making PC parts. Take a look at a few examples here.

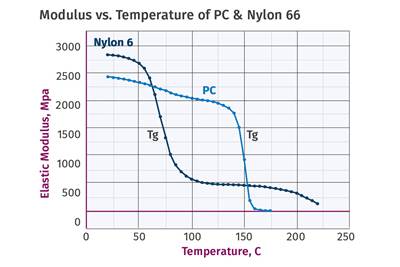

Read MorePart 1: The Importance of Mold Temperature When Processing Polycarbonate

An often overlooked factor in optimizing the ductility of PC is the rate at which the polymer is cooled in the mold.

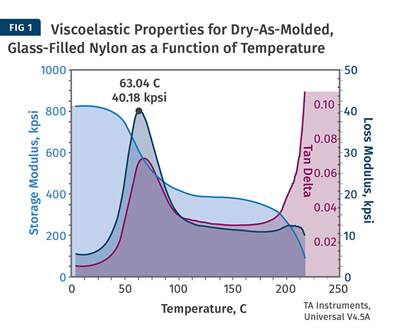

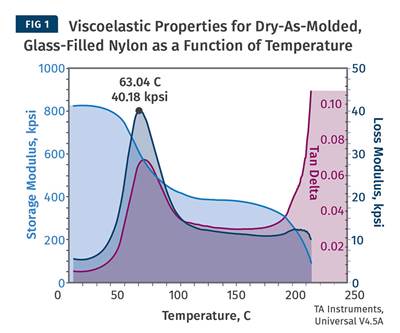

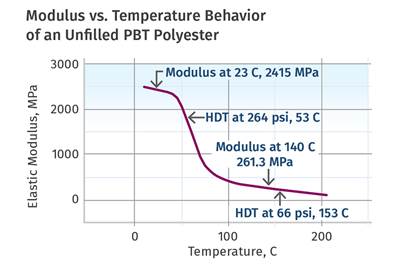

Read MorePart 5: Heat Deflection Temperature vs. Dynamic Mechanical Analysis

In the final part of this five-installment series, we bring DMA to a practical level using the results for glass-filled nylon.

Read MorePart 4: Heat Deflection Temperature vs. Dynamic Mechanical Analysis

The presentation of DMA data can sometimes frustrate users and discourage its adoption. Those unfamiliar with DMA should insist on receiving data relevant to the manner in which the part they are developing will be used.

Read MoreHeat Deflection Temperature vs. Dynamic Mechanical Analysis (Part 3)

DMA provides a rich and detailed picture of polymer performance, and it can be challenging to understand all the things that we can and should know about our materials. But the fact that it may be hard does not mean that it should not be attempted.

Read MorePART 2 Heat Deflection Temperature vs. Dynamic Mechanical Analysis

Here’s a real-world example of a part failure demonstrating why DMA curves have more value than single-point data generated by HDT.

Read MorePart 1: Heat Deflection Temperature vs. Dynamic Mechanical Analysis

Does the industry need a better way of reporting the temperature-dependent behavior of plastics? With DMA, it already has one. But it’s been glacially slow to catch on.

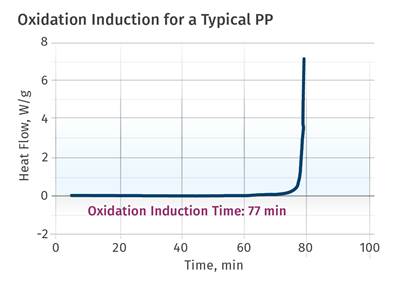

Read MorePart 11: A Processor's Most Important Job

It’s the processors job to ensure molded parts contain enough stabilizer to perform to the expectations of the end use.

Read MoreA Processor’s Most Important Job, Part 10: Fiber-Length Retention

Glass and carbon fibers are often used to increase material strength and modulus. To maintain these properties, the aspect ratio of these fibers must be maintained.

Read More