.jpg;maxWidth=250;quality=70)

Michael Sepe Independent Consultant

Tracing the History of Polymeric Materials: Celluloid & Film Stock

In this series we delve into a discerning look back into the history of our industry and how we all got here.

Read MoreTracing the History of Polymeric Materials--There's More on Celluloid

The invention of Celluloid got the ball rolling for future innovations in materials and processing.

Read MoreTracing the History of Polymeric Materials: Celluloid

In this series we’ll delve into a discerning look back into the history of our industry and how we all got here.

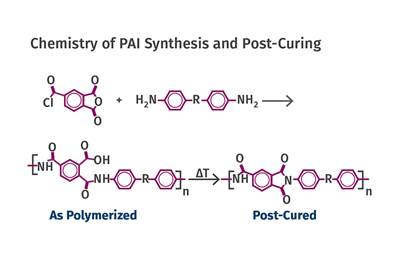

Read MoreMaterials: Annealing Tips for Polyamide-imide, Part 7 of 7

PAI is a material capable of achieving levels of performance that even semi-crystalline engineering polymers like PEEK, PPS, and PPA cannot. But you have to be willing to work for that performance, and the annealing process is an essential part of this.

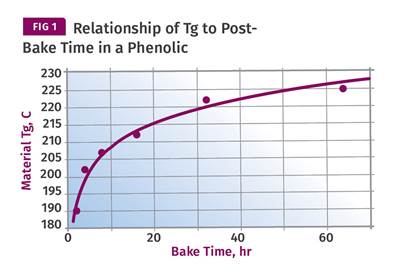

Read MoreMaterials Part 5: Annealing Tips for Crosslinked Polymers

As with semi-crystalline thermoplastics, annealing can be used in thermosetting polymers to obtain a level of crosslinking that may not be possible within the molding cycle.

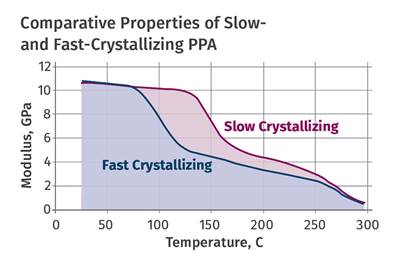

Read MoreMaterials: Annealing Tips for Semi-Crystalline Polymers: Part 4

You can forgo the elevated mold temperatures normally recommended for high-performance semi-crystalline materials. But it’s risky and likely to yield parts that under-perform expectations … assuming that they emerge from the annealing process looking anything like the drawing.

Read MorePart 3 Materials: Annealing Tips for Semicrystalline Polymers

For these polymers, annealing is done to establish a level of crystallinity that cannot be practically obtained within the parameters of a normal molding cycle. Here’s some guidance on setting annealing time and temperature.

Read MoreMaterials: Annealing Tips for Amorphous Polymers, Part 2

In amorphous polymers, annealing is performed to draw down the internal stresses to a level not achievable within the conditions of a normal molding process. But a few parameters are important to achieving the desired results.

Read MoreMaterials Part 1: What Annealing Can Do for Your Process

Relatively rapid cooling rates in processing introduce internal stress. If functional problems in use result, annealing may draw down the stress to levels that may not be achievable during processing.

Read MoreFundamentals of Polyethylene – Part 6: PE Performance

Don’t assume you know everything there is to know about PE because it’s been around so long. Here is yet another example of how the performance of PE is influenced by molecular weight and density.

Read MoreFundamentals of Polyethylene – Part 5: Metallocenes

How the development of new catalysts—notably metallocenes—paved the way for the development of material grades never before possible.

Read MorePolyethylene Fundamentals – Part 4: Failed HDPE Case Study

Injection molders of small fuel tanks learned the hard way that a very small difference in density — 0.6% — could make a large difference in PE stress-crack resistance.

Read More