Tooling

Production Aluminum Tooling: What's Holding You Back?

It might be time to pursue aluminum molds in applications where traditional P20 steel has been specified without giving serious thought to any alternative.

Read MoreBenchmarking Simulation Software: How One Molder Did It

Injection mold simulation has become a standard tool for molders and mold designers.

Read MoreNews in Auxiliaries & Tooling at Fakuma Show

Late last month, Friedrichshafen, Germany, hosted Fakuma 2011, the largest European plastics show of the year, growing to be second in size and importance to the K show in Dusseldorf.

Read MoreDo Flow Simulation 'in the Cloud'

Autodesk Inc., San Rafael, Calif., has just made available a new version of its Moldflow Insight software that takes time-consuming meshing and analysis functions off your desktop and performs them at a remote data center accessed via the Internet.

Read MoreMold Maintenance Training Eases Molder's Growing Pains

Automation Plastics in Aurora, Ohio (automationplastics.com), is a 32-year-old custom injection molder with 50,500 ft² and 30 presses from 35 to 700 tons.

Read MoreWEB EXCLUSIVE: Do Flow Simulation ‘in the Cloud’

Autodesk Inc., San Rafael, Calif., has just made available a new version of its Moldflow Insight software that takes time-consuming meshing and analysis functions off your desktop and performs them at a remote data center accessed via the Internet.

Read MoreNovel Molds & Machinery for Medical Molding

The combined MD&M East and Plastec East shows in N.Y.C. in June presented intriguing developments for medical injection molders.

Read MoreWorld's Smallest Hot-Runner Controller

Measuring 97 x 61 x 30 mm and weighing 135 g, you can hold it in your hand.

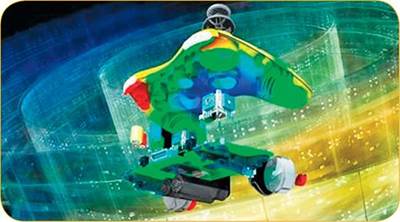

Read MoreOptimize Plug Shape for Thermoforming

Software will adjust the shape to provide more uniform material thickness in the formed part

Read More