Tooling

2018’s Tooling Turndown: Temporary Hiccup or Longer Lasting Correction?

Leading industry consultant charts possible paths for the North American automotive tool and die industry going forward as the outlines of a realignment take shape.

Read MoreHRSflow Moves Into Larger Service Center in Mexico

Hot runner supplier stays in Querétaro but now has more than 10 times the space to operate in.

Read MoreMold Release: Paintable, FDA-Compliant Powder

New Dry-21 paintable PTFE powder mold release is a low-residue, spray-on release with FDA compliance for incidental food contact.

Read MoreAdditive Manufacturing Builds Opportunity in Mold Components

Could additive manufacturing help fill a portion of the skills gap at moldmakers and molders and give them more design flexibility?

Read MoreWhy Ejector Pins Break and How to Prevent It: Part 4

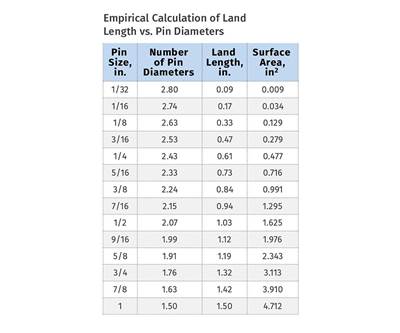

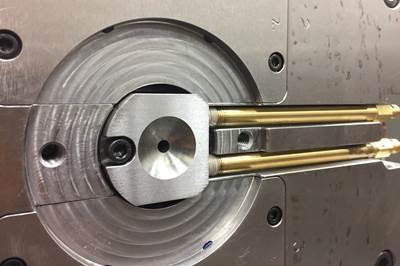

In this installment the focus is on bearing length, clearances, keying, and machining.

Read MoreConformal Cooling Helps Get Heat Out and Cycle Time Down

Conformally cooled sprue bushings help automotive molder reduce cycle times and injection pressures for a high-volume component.

Read MoreNew Mini Mold Components

At Fakuma, Meusburger went “small” with its two newest standard mold components.

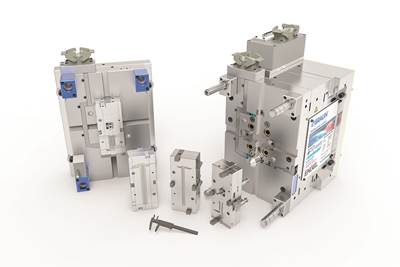

Read MoreAutomated Mold-Insert Changing Via Robot for Short Runs

At Fakuma 2018 show in Germany, Engel Austria (U.S. office in York, Pa.) is presenting three premieres in one exhibit.

Read MoreINCOE Consolidates Michigan Facilities Into New Global Headquarters

Over the month of August, the global hot runner supplier moved its three existing operations in the Detroit area into a new 138,000-ft² facility in Auburn Hills.

Read More