Resin Conveying

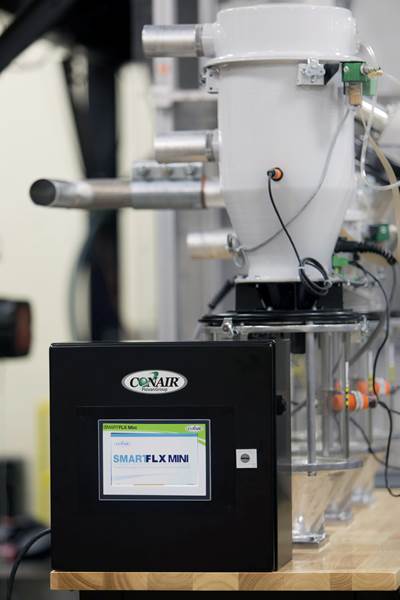

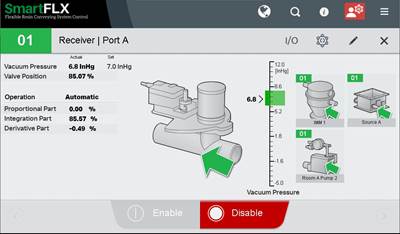

Mini Control Offers Central Conveying for Small Plants, Work Cells

NPE2024: System supports vacuum conveying systems with up to three vacuum pumps and a maximum of up to 12 receivers.

Read MoreResin-Selection Station Conveys Material on Demand

NPE2024: Powerful, space- and labor-saving station makes the connections and conveys material automatically on command.

Read More5-Component 'Plug-and-Play' Conveying System

NPE2024: VAC-U-MAX Signature Series Vacuum Conveyors are a “plug-and-play” solution for conveying powders, pellets, flakes, fibers, wood flour, pigments and more to processing lines.

Read MoreAutomated Resin Management and Blending System for Tight Spaces

NPE2024: Designed for new and existing operations with up to 10 machines and limited available space.

Read MoreLoaders, Blenders Made Specifically for Medical Processors

NPE2024: FDA-compliant auxiliaries suited for injection, extrusion, blow molding.

Read MoreCompact, Mobile Dryer Has Unique Conveying Capabilities

NPE2024: Mobile dryer includes closed-loop conveying to minimize the use of ambient air for resin movement.

Read MoreConveying System is AI-Driven

NPE2024: New system creates and maintains optimal source-to-destination material flows.

Read MoreSoftware Helps Processors Make Better Business Decisions

NPE2024: Tracker Monitoring and Reporting Software supports ISO reporting and material validation, including PCR usage and equipment status monitoring.

Read MoreFinding Efficiencies in How Components Work Together

Auxiliary systems are vital to the proper functioning of a plastic processing line, and they can be a source of major cost and efficiency improvements.

Read MorePiovanGroup Rebrands, with Mostly Minor Name Changes

For the most part, subsidiary company names will remain, with slight modifications meant to enhance the Group’s identity.

Read More