Resin Conveying

Material Handling: Screw Conveyor Goes Mobile, Adds Trough Hopper

Two new models of flexible screw conveyors are available from Flexicon Corp., Bethlehem, Pa.

Read MoreAuxiliaries: New Auxiliaries for Blending, Loading, Cooling & Granulating

Wittmann Battenfeld showed a variety of new and modified auxiliary equipment at the Fakuma show.

Read MoreMaterials Handling: Enclosed Bulk-Bag Discharger

A new Bulk-Out Model BFC bulk-bag discharger from Flexicon Corp.., Bethlehem, Pa., has an enclosure to contain dust escaping through the seams or fabric of unlined bulk bags.

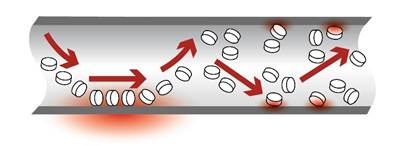

Read MoreNew Wave Technology Solves Biggest Conveying Problems

New wave conveying technology from Conair gently moves your materials at comparable output rates without damaging resins.

Read MoreAdvanced Blending Solutions Expands Space, Staff and Capabilities

Advanced Blending Solutions (ABS; Wallace, Mich.) has added 40,000-ft to its facility, including space for assembly, warehouse, and offices.

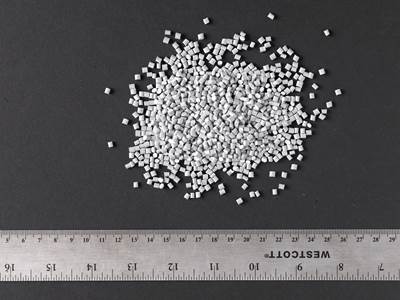

Read MoreMedical Molder Cuts Resin Dust to Boost Quality & Output

As a result, part yields are boosted from only 3% to 60% or more.

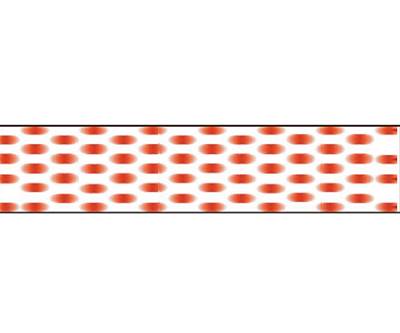

Read MoreKeep Dust and Angel Hair Out of Your Process

Angel hair, fines, and dust can adversely impact any type of plastics production—from resin manufacturing itself to molding and other processes. Here’s how to solve it.

Read MoreNew Source for Silo Loaders and Resin-Cleaning Systems

ADG Solutions now offers silo-loading and resin-cleaning systems—built by Italy’s Lorandi Silos—to plastics processors that purchase resin in gaylords or super sacks.

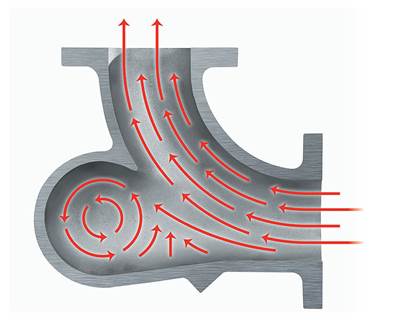

Read MorePP Compounder Elbows Out Production Snafus

The Plastics Group of America eliminates monthly production stoppages, improves quality, and slashes maintenance expenses by installing new elbows on a pneumatic conveying line.

Read More10 Things to Know When Specifying Vacuum Conveying Systems for Powders

The priority is to maximize movement of powders while minimizing dust exposure.

Read More