monitoring

Agr International Adds PET Bottle Line Optimization Services

Agr’s new Process Performance and Optimization Group can provide production-line auditing and optimization planning, as well as job-specific services such as recipe design and startup assistance.

Read MorePelletizing: Extrusion Control System Extended to Pelletizing

First unit in place at a rotomolder for recycling scrap.

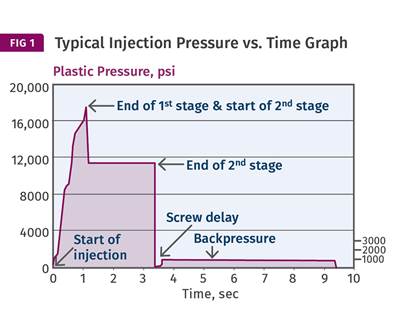

Read MoreHow to Quickly Verify Your Machine & Process Setpoints

For a quick check of your process setup, the injection-pressure-vs.-time graph is your best tool.

Read MoreMaterial Handling: Sensor Measures Material Consumption at Hopper

Unit tracks primary material consumption and gives information on total consumption after each production order.

Read MorePower Controller Governs Temperature With Precision

Modular multi-loop power controller for resistive loads can adjust to customer requirements, allowing up to 1,512 outlets to be controlled individually.

Read MoreInjection Molding: Simplified Cavity-Pressure Control And Process/Production Monitoring

Cavity Eye provides innovative cavity sensors and data-transmission devices that plug into molds, machines, and auxiliaries.

Read MoreInjection Molding: Adaptive Shot-Size Control Now Available for Thermosets

KraussMaffei control for uniform shot weight now can be used with granulated thermosets, BMC/SMC, and liquid or solid silicones.

Read MoreMaterial Handling: New Battery-Powered Laser Level Sensor

Allows use of level sensors on silos or in remote locations where inventory monitoring has not been feasible.

Read MoreControls: High Horsepower Controls For Hazardous Locations

NEMA 12 main power panel, housing high-voltage VFDs and motor protection fusing is installed in a non-classified area and wired to a NEMA 7/9 operator station.

Read MoreAre We Having a Good Day? Real-Time Production Data Has Answers for a Custom Blow Molder

“Information automation” is one of the keys to running a successful custom blow molding 大象传媒 for Meredith-Springfield Associates.

Read More