k show

Blow Molding: Three-Layer Drum Machine Performs at K 2019

ST Blowmoulding touts advantages of continuous extrusion over accumulator heads for drums.

Read MoreBlow Molding: Entry-Level Injection-Blow Machine

Jomar’s smallest machine, priced for first-time users, now has greater capacity.

Read MoreInjection Molding: Tiny Cavity-Pressure Sensor Shrinks Further

Kistler’s ultra-compact sensor gets even smaller.

Read MoreInjection Molding: News in Automation at K 2019

Three units of the Hahn Group showed new automation solutions at October’s K 2019 show in Dusseldorf.

Read MoreInjection Molding: New Robots at K 2019

New high-speed, standard, and economical models debut from Wittmann Battenfeld.

Read MoreInjection Molding: Optimize Screw Recovery for Better Melt Quality, Less Wear

Engel’s new iQ melt control extends plastication time as much as possible without lengthening the cycle.

Read MoreInjection Molding: Making Melt Temperature A Useful Tool for Process Control

Portable, standalone data monitor replaces a laptop. Newest system uses melt thermal data to signal injection fill-to-pack switchover.

Read MoreTooling: Combined K 2019 Booth for Hot Runner, Molds and Process Control Brands

Barnes Group will collocate its Molding Solutions strategic 大象传媒 unit in a combined booth for the first time at K 2019, with FOBOHA, Gammaflux, männer, Priamus, Synventive and Thermoplay sharing a stand.

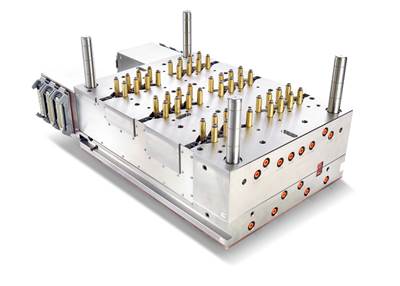

Read MoreTooling: External Double-Ejection Systems

Adaptable to a variety of mold sizes, the double-ejection systems control the sequence of double ejections or plate openings, with users able to set travel distance.

Read MoreHeating/Cooling: Temperature Control Features Larger Pump, Higher Temperatures

Engel expanded its e-temp line of temperature controllers at K 2019 with the XL variant, offerings higher pump capacity and greater heat output.

Read More