Injection Molding

How to Establish an Acceptable Range for Pressure at Transfer

Pressure at transfer tells you the viscosity of the resin, providing the fill time is the same. Monitoring pressure at transfer—or better yet, the integral under the pressure vs. time curve—provides insight into the process.

Read MoreMelt Flow Rate Testing—Part 6

Once degradation has been established, the discussion inevitably turns to how it happened. It might be expected that the answer to this question is widely known. Not so. The good news is that the influences that cause polymer degradation during processing are few.

Read MoreInjection Molding at K 2013: Doing More with Less

More productivity with less energy consumption and capital investment; more operations in the machine or manufacturing cell with less time, labor, energy, and capital鈥攖hese were the common themes of injection molding exhibits at October鈥檚 K 2013 show.

Read MoreMinimizing Black Specks

Black specks in molded parts are one of the most infuriating problems to resolve on the shop floor. Here's how to fix them.

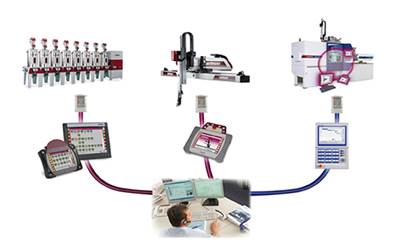

Read MoreWeb Connectivity: the ‘Missing Link’ To Molding Machines & Auxiliaries

Web services technology is being utilized today by many molding companies to enhance their molding operations performance, expand uptime, and obtain supplier support in shorter time for very low cost.

Read MoreHeadlines from the K 2013 Show

Here’s just a taste of the innovations on display, a selection of the top headlines not covered in our September show preview.

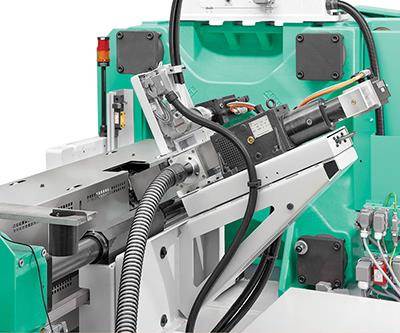

Read MoreArburg Grabs Spotlight at K 2013

WEB EXCLUSIVE: At K 2013, injection machine builder introduces the Freeformer, a novel machine for additive manufacturing.. But there was plenty to see in hot runners, LSR processing, and lightweighting as well.

Read MoreArburg Causes Buzz at K Show with New 3D Printer

One of the most talked-about news announcements at the K 2013 in Dusseldorf, which wrapped up last week, was Arburg’s introduction of an ink-jet type 3D printer.

Read MoreNew LSR Technical Center Opens in Ohio

Shin-Etsu facility houses two molds, Arburg press, Elmet dosing system.

Read MoreSuper-Lightweight PET Bottles

Lightest ever still water, hot-fill PET bottles debut at Drinktec sow.

Read More