Injection Molding

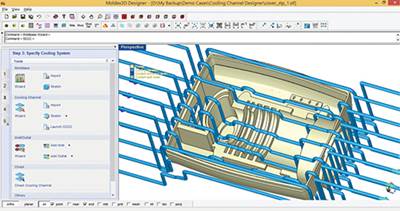

INJECTION MOLDING: Mold Simulation Software Gains Speed and New Functionality

It's faster, easier to use, and supports more sophisticated modeling.

Read MoreHoover’s Huge Former Molding Plant Is on the Block

With 150 presses, it's said to be 'the largest injection molding plant West of the Mississippi.'

Read MoreBarrel Repair: When Does It Make Sense?

Repairing a barrel can save you time and money vs. buying a brand-new one. But it’s not an easy fix and not even always possible.

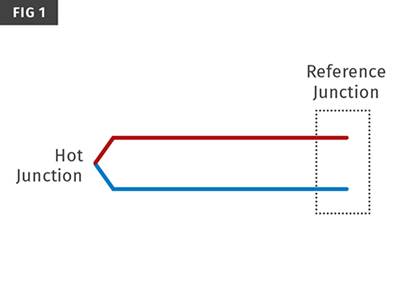

Read MoreReduce Hot-Runner Downtime With Proper Troubleshooting

Solve your problem faster by adopting a systematic approach. Here’s how to get going.

Read MoreB&B Molders Sticks to Its Core— Core Values & Core Competencies

To compete in today’s market, you need good technology, but you also need to know what you stand for and what you’re good at.

Read MoreWhat Processors Are Doing To Bridge the Skills Gap

Seasoned technicians are leaving, and replacing them with youngsters is a challenge. But some processors have taken dramatic initiatives to change how young people think about manufacturing and are bringing the next generation into the fold.

Read MoreRFID Boosts Production Efficiency For Bumper Molder

RFID technology significantly improves ‘error-proofing’ and productivity from molding to final fabrication.

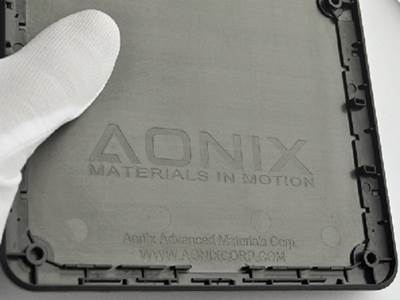

Read MoreTablet Computer Shell Demonstrates Thermoplastic Composite Process

Advanced materials and high-speed molding machines comprise a new turnkey system for thermoplastic composites.

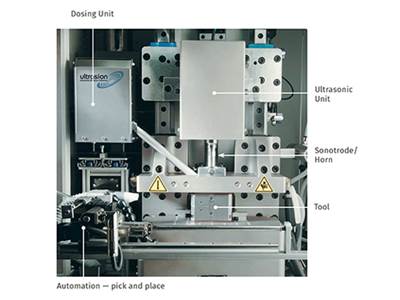

Read MoreMold Micro Parts with Ultrasonic Technology

New machine utilizes ultrasonic waves to melt plastics for micromolding, as opposed to the shear and conductive heating used in standard processes.

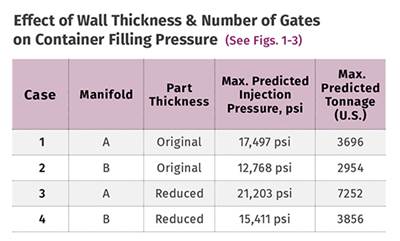

Read MoreINJECTION MOLDING: The Importance of Nominal Wall For Lightweighting Molded Parts

Establishing a nominal wall is one of the most important decisions an engineer makes when designing parts. Understanding how design changes will impact the manufacturing process is critical to ensure the part performs as expected.

Read More