Heating & Cooling

New Physical Foaming Process for Injection Molding

Linde will introduce a new physical foaming process for injection molding and show off CO2-based gas-assist and mold-cooling technologies.

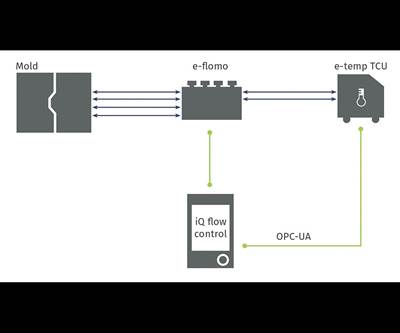

Read MoreHeating/Cooling: Energy-Saving Mold-Temperature Control Comes to NPE

Electronic flow control is paired with a variable-speed TCU pump to achieve optimum cooling with the minimum energy required.

Read MoreInjection Molding: Wittmann’s U.S. Debut of Two Machines, New Robots & Auxiliaries at NPE

A high-speed packaging machine, two-shot micromolder, and new high-end and economical robots, plus several new auxiliaries bow in at NPE.

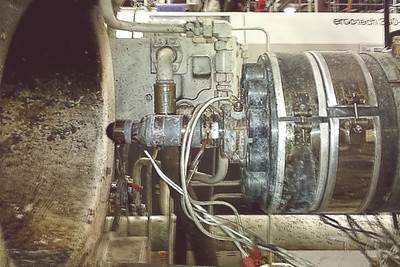

Read MoreKeeping The Heat on The Barrel

Noncontact radiant heaters embedded in ceramic-fiber insulation save energy and keep heat from being lost into the plant environment.

Read MoreCentral Chiller Uses New Control To Maximize Cooling, Minimize Energy Use

Chiller calculates and uses the lowest allowable refrigerant pressure to maximize performance and deliver energy savings.

Read MoreProcess Cooling: Variable-Speed Chillers Boast Dramatic Energy Savings

Variable-speed, air-cooled chillers from Delta T Systems complement water-cooled versions announced earlier.

Read MoreR&D Effort to Boost Efficiency in Thermoformed Packaging

Key is tiny, individually controlled ceramic heaters that allows optimal regulation of film thickness.

Read MoreAir-Ring Upgrade Pumps Up the Output

Film processor Dallas Plastics boosts throughput by as much as 40% by retrofitting a new air ring—without the need for IBC.

Read MoreInjection Molding: Nozzle Heaters & Thermocouples: A Case of Wiring Done Wrong

Incorrect placement of wires for these components frustrates molders and costs them money to boot.

Read MoreAn Inside Look at Turbulent Flow

Years of talk about observing and studying coolant flow in a clear simulated cooling channel finally becomes a reality. Here’s how it all came together, and what it all means.

Watch