Extrusion

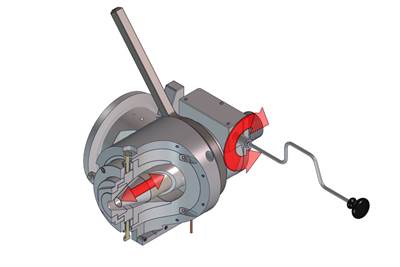

Crosshead Die for Elastomers Adjusts Easily

NPE2024: Mechanically actuated gum space adjustment requires only ordinary socket wrench.

Read More'Hybrid' Die Design Eliminates Weld Lines, Cuts Stagnation

NPE2024: Newest extrusion tool retains benefits of previous design and adds features to boost quality.

Read MoreBlown Film Lines Are Fully Customized

NPE2024: Systems can be furnished for single- to nine-layer for barrier applications.

Read MoreInteractive Training for Injection, Extrusion and Other Processes

Paulson has four in-booth stations demonstrating its various training solutions.

Read MoreEnhanced Temperature Controls for Hot Runners, Extrusion and Packaging

NPE2024: Athena introduces expanded hot-runner controller with up to 120 zones, plus updated panel-mount “universal” temperature/process control.

Read MoreDownstream Line for High-Precision Profiles

NPE2024: System features calibration and cooling tables, haul-offs, cutting units and tilting tables.

Read MoreScrew Design Tips to Boost Productivity

In this collection of articles, two of the industry’s foremost authorities on screw design — Jim Frankland and Mark Spalding — offer their sage advice on screw design...what works, what doesn’t, and what to look for when things start going wrong.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreCutting-Edge Measurement and Control Devices for Extrusion

NPE2024: Sikora is showcasing a range of cutting-edge equipment designed to meet the high standards of the hose, tube and pipe market.

Read MoreCoiling System Features Automated Spool Removal

NPE2024: Designed for wire and cable and tubing, system is equipped with a Yaskawa cobot for automated spool removal.

Read More