color

Injection Molder Changes Up Color Changes

An injection molder of trash cans, pallets, totes and other plus-size components, Rehrig Pacific’s machine fleet is composed of larger tonnage presses whose size makes material changes at the feed throat a potentially dizzying exercise.

Read MoreAdditive Masterbatches for Monomaterial PE Film Applications

Ampacet’s Biax4CE portfolio of additives and white color concentrates designed for MDO-PE and BOPE applications.

Read MoreDSM Launches an AI Powered Color & Mechanical Properties Prediction Tool

Called Lucidiris, this prediction tool can reduce time to market when developing colors of high-performance materials for a variety of applications.

Read MoreNovel System Produces Color on Demand

Ampacet’s FluxQF technology features a quick-dispersion universal carrier with novel machinery that provides automated color blending in quantities down to 50 lb.

Read MoreUnderstanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read MoreSorting Mixed Plastics by Color and Type

Steinert will demonstrate plastic sorting technology at K 2022.

Read MoreSPE’s Automotive Division Names 2022 Hall of Fame Winner

First mold-in color weatherable grille used on the 1987 VW Golf to be celebrated at the 51st annual SPE Automotive Innovation Awards Competition & Gala.

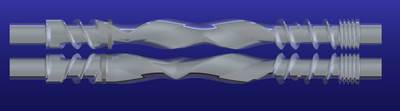

Read MoreHigh-Dispersion Rotor for Compact Processor

Billed as ideal for processing fiber grade, high color carbon black, and color concentrates.

Read MoreCoke Makes Bottle Changes to Boost Recycling

Sprite bottles will be clear, while Dasani bottles will be made with recycled plastic.

Read MoreSpecialty Purging Compounds Optimize Color and Material Changeovers

Selecting of the correct purging compound can speed up material and color changeover time and reduce scrap. You’ll even save on material.

Watch