close up on technology

Fast, Precise Machine Helps Tubing Processor Make the Cut

Instead of turning down a job or farming out cutting to another company because of downstream bottlenecks, Eagle Elastomer can now handle all extrusion process functions in-house.

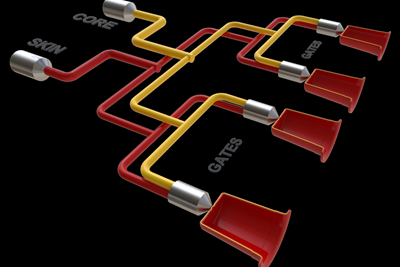

Read MoreA Clearer View of Kortec's Co-injection Technology

Two decades after it was created and five years since it joined up with Milacron and its Mold-Masters brand, Kortec’s co-injection technology can yet provoke misunderstanding among processors.

Read MoreRethinking Machine Nozzle Tips: Hybrid Design Boosts Flexibility, Efficiency

New cold-sprue and hot-runner nozzle tips promise utility across a wide range of materials, eliminating the need to swap out different tips for different jobs while also promising to solve scrap and process issues.

Read MoreNylon 66 Replacement With the Aid of a Materials-Savvy Distributor

PolySource helped two OEMs—one in beverage packaging, the other in winter sports vehicles—transition from nylon 66 to polyketone (POK) compounds after parts failure.

Read MoreWater Injection Beats Gas Assist in Lightweighting Car Door Panel

Renault’s conversion from metal-frame construction to plastics prototype switched from gas assist to water injection. Here’s why and how.

Read MoreLSR Molders Now Can Tailor Cure Speed, Temperature & Durometer

Elkem’s LSR Select is enabling faster cures at lower temperatures and custom durometer blends. Dosing equipment has caught up with capabilities of this novel material system.

Read MoreSuper-Compact Auxiliary Injection And Intrusion Units

Unusually compact secondary injectors outfit standard presses for multicomponent and sandwich molding.

Read MoreMachine Builders Join Forces On Novel ‘Direct-to-Sheet’ Technology

PTi, Farrel Pomini team on sustainable technology platform that combines compounding and sheet extrusion at extremely high filler loadings.

Read MoreCobots Help Molder Find ‘Right Balance’ Between People and Automation

Short-run, quick-turn custom molder uses collaborative robots selectively to make people more productive.

Read MoreIs a New Crop of Processors Emerging with More Materials Know-How?

Recent graduates of plastics education programs appear to be closing a longstanding gap in processors' contributions to materials selection for applications.

Read More