Blow Molding

Paulson: Fill the Skills Gap…By Training

Training may not be a glitzy as seeing a new machine at a trade show, but the payback is just as real...and it just might help you find and retain employees.

Read MoreNPE2018 New Technology Focus: Foam Fascination

A new physical foaming process and a significant enhancement of the MuCell process attract attention at the show.

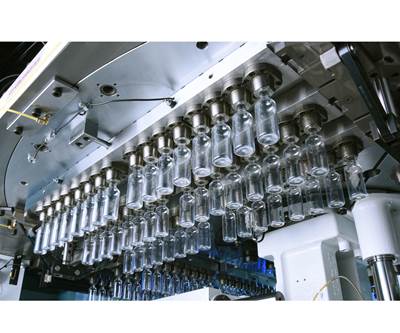

Read MoreInjection-Blow Molding Line Gets a Technology Makeover

Jomar is adding servo-hydraulic drives and Industry 4.0 capabilities to established workhorse machines.

Read MoreGraham Shows Advances in Controls, Extrusion, Blow Molding

New extruders and systems for sheet and tubing along with the first showing of an accumulator-head blow molder.

Read MoreNissei ASB Displays Its Arsenal of PET Technologies

From unprecedented productivity of small bottles to production of wide-mouth jars for hot filling and pasteurization, Nissei ASB fields the largest and most varied range of PET stretch-blow technologies at NPE.

Read MoreBlow and Fill a Bottle Simultaneously: Learn More at NPE2018

Unique technology for blowing a plastic bottle with the liquid contents instead of air is being highlighted at NPE2018 this week.

Read MoreBottles and Blow Molding? You Bet!

Dedicated 65,000-nsf zone in the South Hall features manufacturers and suppliers to the bottle blow molding industry, as well technical forums and networking opportunities.

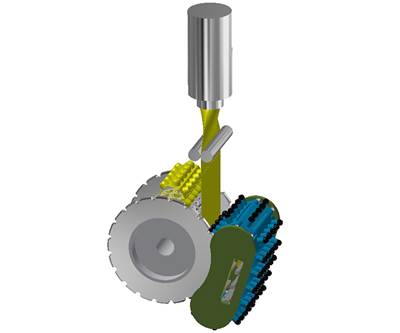

Read MoreNew Equipment Designs to Spark Your Imagination

Wilmington Machinery offers novel ideas for blow molding, injection molding, thermoforming, and more.

Read MoreMilacron Is ‘Going Big’ at NPE2018

Milacron is emphasizing large-tonnage injection presses, enhanced customer service to maximize their uptime, and speed—both speedy delivery of parts and suppies, and products that speed up production for their customers.

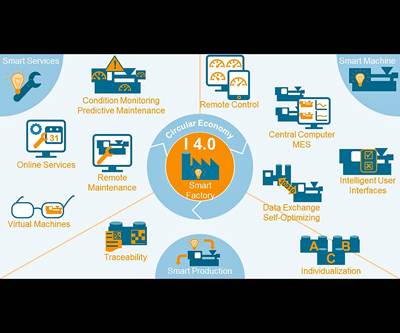

Read MoreNPE2018 New Technology Focus: The ‘4.0’ Revolution

Injection and blow molding and robot suppliers are making Industry 4.0 the most prevalent theme of the show.

Read More