best practices

ICYMI: January Roundup

In case you missed it, here’s a short recap of the articles that our readers are taking note of.

Read MoreHigh Quality PCR With Mechanical Recycling Is Within Reach

Successful mechanical recycling of postconsumer materials requires market analysis, understanding requirements and building relationships across the value chain.

Read MoreTo Cushion or Not To Cushion: That Is the Question

Whether or not your process setup includes adding cushion depends on multiple factors, including the part being molded. Learn when and how to effectively apply cushion in your process.

Read MoreProcessors: Gear Up to Handle More Regrind

Plastics auxiliary and primary processing equipment was optimized for running pellets; here’s how you can adjust to the bulk density differences of flake and regrind in drying, conveying, mixing, feeding and processing.

Read MorePlastics Technology Year in Review: Your Favorite Reads of 2024

A year-end review of the top stories showcasing industry trends, advancements and expert insights. Revisit the articles that captured the attention of the plastics community.

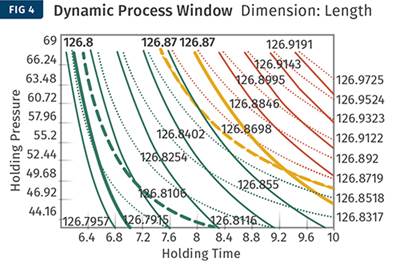

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

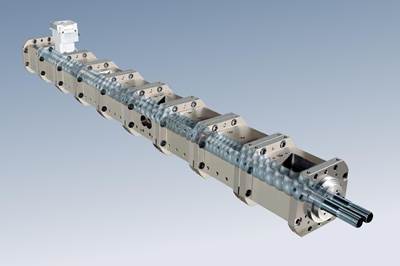

Read MoreHow to Configure Your Twin-Screw Barrel Layout

In twin-screw compounding, most engineers recognize the benefits of being able to configure screw elements. Here’s what you need to know about sequencing barrel sections.

Read MoreImportant Factors and Approaches to Estimating Residence Time in Injection Molding

Residence time can have a dramatic impact on part quality and production efficiency but determining its value can be tricky. Use these methods and formulas to accurately measure residence time and enable it to inform everything from scheduling jobs to optimizing a process.

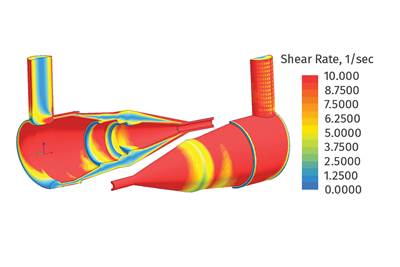

Read MorePart 2 Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Simulation can determine whether a die has regions of low shear rate and shear stress on the metal surface where the polymer would ultimately degrade, and can help processors design dies better suited for their projects.

Read MoreFighting Dust and Noise in Regrind Operations

Mayhew Basque Plastics implemented lower speed granulators to deal with challenging materials.

Read More