Additive Manufacturing

3D Printing Method Fabricates Complex Metal Plastic Composite Structures

Researchers from Japan and Singapore have developed a new 3D printing technique to create precise metal patterns on the surfaces of 3D plastic structures to target next generation electronics.

Read MoreLarge-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

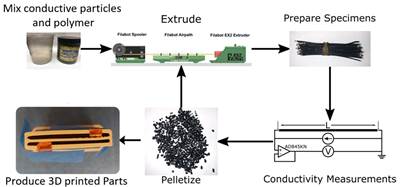

Read More3D-Printed Parts With Inherent Functionality Throughout

Patent-pending technology evenly disperses sensor particles in fused deposition modeling (FDM) filaments resulting in printed parts with inherent sensing capabilities.

Read MoreNexa3D Announces Technology, Service Partnerships

The maker of high-speed industrial 3d polymer printers announced a deal with DyeMansion to automate post-printing operations, as well as adoption of its tech by Xometry and QuickParts.

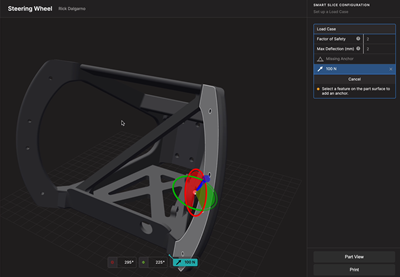

Read MoreMarkforged Introduces New Simulation Package for its Additive Manufacturing Software

Launched at Formnext, Simulation seeks to replace the slow and costly design/print/break testing cycles with virtual testing.

Read MoreAddman Acquires Harbec

The metalworking and metal and polymer additive manufacturing collective formed in 2020 has purchased the 45-yr-old injection molder and moldmaker.

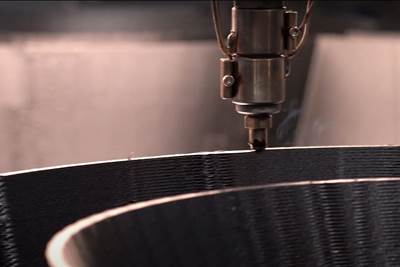

Read MoreKraussMaffei Launches Two Additive Manufacturing Lines at K 2022

Long established in injection molding, extrusion and polyurethane reaction process machinery, 184-yr-old KraussMaffei prepares to enter the industrial additive manufacturing market.

WatchWear-Resistant Blue Laser-Sintering Material Ensures Food Safety

New iglide i6Blue powder from igus is wear resistant and self lubricating; its blue color aids food-safety goals.

Read MoreHow Additive Manufacturing Can Help, not Hinder, Injection Moldability of New Designs

Four cost drivers—design for moldability, mold-base size, internal componentry, polish/custom finishing—dictate the financial and processing success of a molded part design. Learn how 3D printing can assist this process, while also understanding its potential pitfalls.

Read MoreMetal 3D-Printing Technology Targeting Tooling Is Launched

Following successful beta testing of the P-200 printer and TrueShape technology, Mantle has commercially launched its metal 3D printing system, with deliveries planned for the first half of 2023.

Read More