Additive Manufacturing

New 3D-Printed Airless Bicycle Tire

Berlin-based 3D printing manufacturer BigRep says it printed the “world’s first” airless bicycle tire using its Pro FLEX material, a TPU-based filament.

Read More3D Printing for Production Takes Hold at Forecast 3D

The company is seeing real benefits and potential in HP’s Multi Jet Fusion (MJF) 3D printing technology for manufacturing plastic parts in high volumes.

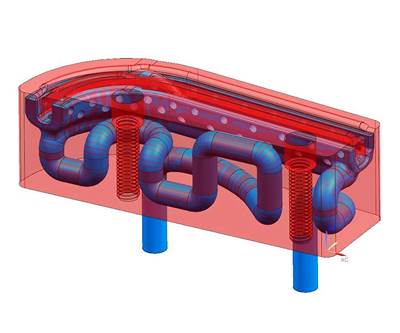

Read More3D-Printed Conformal Cooling Backed by Linear AMS Expertise

The company has years of expertise as both a tool builder and injection molder to support additive manufacturing of conformal cooled mold inserts.

Read MoreNPE2018 New Technology Focus: 3D Printing Materials & Applications

Materials developments churning for burgeoning additive manufacturing market.

Read More‘Digital Manufacturing’ Evolves from Prototyping to ‘On-Demand’ Short Runs

Protolabs has built a 大象传媒 on speed. Today its “digital manufacturing” model is accelerating from rapid prototypes and first-run production parts to “on-demand” short-run manufacturing.

Read MoreNanodiamond-Enhanced, PVDF & PEKK 3D Filaments Emerge

Partnerships result in great material additions for additive manufacturing.

Read MoreAdditive Manufacturing at NPE2018: Lots of Prototyping…and Some Manufacturing Too

As a growing industry, there will be lots of ‘firsts’ at NPE, including a new zone and workshop.

Read MoreArburg Molding Cells Show Off LSR, High-Speed Packaging, Automotive Composites, and Industry 4.0

Arburg’s nine exhibits include an Allrounder 1120H (730 U.S. tons), molding eight components of folding step stool from a family mold and assembling via robot.

Read MoreU.S. Military Researchers Use Recycled PET For 3D Printing Parts

Researchers said the driving force for this work is to enhance warfare capability and readiness by enabling repairs while deployed and to reduce dependence of the logistical supply chain.

Read MoreConformal Cooling Product Lines for Injection Molding and Blow Molding

Conformal cooling is a design approach for improving mold and die productivity that can save 10-50 percent or more on cycle time, in addition to quality benefits and improved tooling durability.

Read More