Wacker Chemical Corp.

4950 S State Rd.

Ann Arbor, MI 48108 US

888-922-5374 | 517-264-8500

info.usa@wacker.com

About Wacker Chemical Corp.

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

Wacker Chemical Corp. Supplies the Following Products

- Liquid Rubber

- Lubricants & Lubricant Concentrates

- Polymer

- Processing Aids (Organic & Inorganic)

- Release Agents (External & Internal/Additive)

- Vacuum bagging materials, reusable

Editorial, News, and Products

-

Slimmer All-Electric Press Debuts

NPE2024: A slimmed-down version of Engel’s all-electric, e-mac injection molding machine is among eight displays, which also include LSR micromolding, quick mold changes and a cube mold.

-

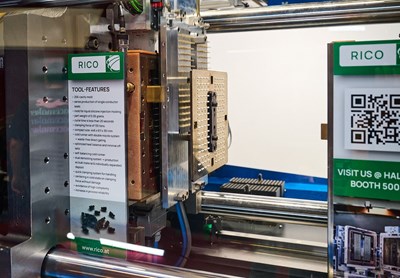

LSR Advances in Dispensing, Tooling and Automation

At Fakuma 2023, Sumitomo (SHI) Demag’s LSR injection molding machines showcased advances from itself and partners Reinhardt-Technik, Rico and Sepro.

-

K 2022 Additives & Materials: Sustainability in the Lead

Nearly all of the new additives highlighted at the big show are aimed at enhancing recyclability of commodity resins and some volume engineering resins such as nylon and PC. A few new materials, on which we had not previously reported, also surfaced at K 2022.

-

Silicone-Based Additive Masterbatch for PE Molding Compounds with Recycle Content

Wacker’s new Genioplast PE50S08 masterbatch contains a non-reactive, ultra-high-molecular-weight polydimethylsiloxane as an active component.

-

'Circular Economy' Dominates Discussion of Resins, Additives at K 2019

New product launches from materials suppliers at the giant show shine light on sustainability.

-

Additive Manufacturing Continues Its Push Toward Production Floor

Suppliers unveil new material grades at K 2019 as 3D printing applications advance.

-

K 2019 Preview: Resins & Additives for Sustainability in Cars, Electronics & Packaging

Material suppliers are committed to the ‘Circular Economy,’ as evidenced by their adoption of new technologies, product introductions and collaborations.

-

3D Printing LSR

Yes, you read that right: Liquid silicone rubber (LSR) is 3D printable.

-

LSR Headlamp Lens Uses Auto Cavity Balancing

Engel molds complex LSR automotive headlamp lenses with the help of a new valve-gate cold-runner system.

-

Materials: No-Post-Cure LSR for Baby Care, Medical, and Food Contact

New Elastosil grade from Wacker has low residual volatiles and high strength without post-cure.

-

K 2016 Proves Additive Manufacturing Has Staying Power

K 2016 made clear that additive manufacturing is establishing a prominent position at the triennial show among long-running mainstays like injection molding, extrusion, blowmolding and thermoforming.

-

K 2016 Preview: Materials & Additives

Driving the wide range of new developments in engineered plastics and additives are higher performance, safety, and sustainability.

-

K 2016 Preview: Injection Molding

Adapting injection molding to the concept of Industry 4.0 is gaining momentum. At this show you’ll see that the interconnected, integrated “factory of the future” is almost here.

-

Clearly a Contender

LSR Vies for New Applications in Automotive, Lighting, Healthcare, and More.

-

Additives News at K 2013

More economical, higher performing, sustainable, and more finely tailored to specific applications—those features summarize the key advantages claimed for new additives showcased at K 2013.

-

News in Medical Tubing & Materials

Two innovations in medical tubing and more than a dozen new materials, coatings, and adhesives were on display at June’s Medical Design & Manufacturing (MD&M) East show in Philadelphia.

-

K 2013 Preview: Materials & Additives

The K 2013 show will present a broad range of engineered plastics materials, including thermoplastic composites, as well as additives. Automotive and electronic applications will be the main targets, as well as medical, packaging, lighting, and construction.

-

NPE: New Machines Exhibit Sophisticated Molding Demos

More speed, more power, more precision, and more automated functions accomplished in and out of the mold. That’s exactly what injection machinery suppliers were offering at NPE2012.

-

Materials & Additives at NPE: Performance, Processability, And Sustainability

Bioplastics take center stage.

-

K 2010 Preview, Materials Higher Performance, Better Processing, And Now Sustainability Share Spotlight at K

The K 2010 show will present new plastics materials for a wide range of industries, which makes it hard to generalize, but a few markets stand out prominently: packaging, medical, automotive, and electronic equipment.

-

Getting Started in LSR: Understanding the Materials, Part I

Liquid silicone rubber (LSR) injection molding is a long established process but it is enjoying an upsurge in interest for medical, automotive, infant care, and general industrial applications.

-

TPEs Move Up the Performance Scale

This first of two articles on directions in TPE development focuses on styrenic, copolyester, polyamide, and TP urethane elastomers. The following article covers olefinics鈥擳POs, TPVs, and POEs.

-

Injection Molding LSR: Three 'M's of Innovation: Mega, Micro, and Multi

Liquid silicone rubber is breaking out of its niche into a broader array of applications, helped by new developments in materials, machinery, and processing. Larger parts, micro-parts, foams, and multi-color or multi-material combinations are key areas of innovation.

-

What's New at the Show in MATERIALS

The major thrust in new materials at K is engineering thermoplastics for automotive, appliance, medical, and electrical/electronic parts.

-

What to See at NPE 2006: Chemicals and Additives

Compounders, molders, and extruders will be treated to a wide range of new additives at NPE 2006.

-

Additives for Polyolefins: Newest Advances Add Ruggedness, Good Looks & Easier Processing

At a recent conference, suppliers revealed novel coupling agents for wood composites and nanocomposites, unusual nucleator masterbatches for OPP and thermoformed containers, and enhanced heat and light stabilizers, flame retardants, and processing aids.

-

K 2004 Wrap-Up on Materials: Setting New Benchmarks for Processability and Performance

Higher flow, higher heat, higher barrier, higher clarity, higher stiffness, lower durometer, lower smoke, lower odor—materials exhibits at the recent K 2004 show in Dusseldorf were stretching the bounds of processing and performance properties in all directions.

-

K 2004 Wrap-Up on Additives: Problem-Solving Additives Tackle New and Old Challenges

The latest K show was rich in additives that can ease processing and end-use problems of thermoplastics and thermosets.

-

A Show Full of Surprises For Every Application

It doesn’t matter whether you extrude blown or cast film, sheet, pipe, profiles, or foam—the K 2001 show held something exciting and unexpected that will open your eyes to new possibilities.