Upgraded Collating System for Complex, Unstable Bottles

Sidel has improved its Cermex ProSelex flexible collating system, which is now faster, more compact and easier to change over.

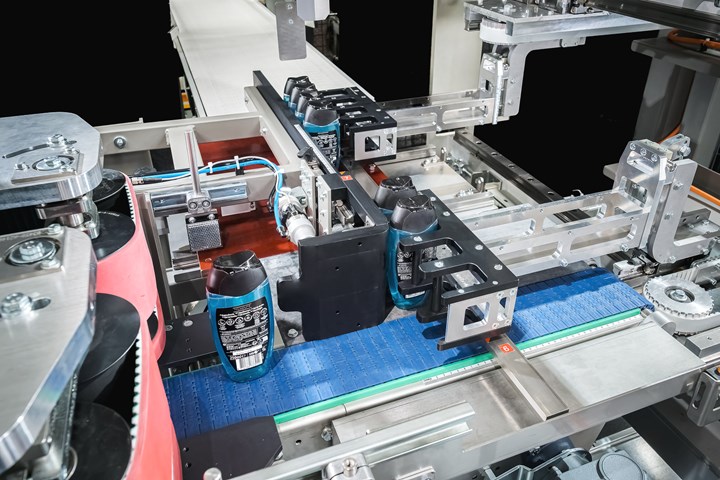

Faster but gentle handling of creative but unstable bottle shapes is claimed for the new generation of Cermex ProSelex collating system from Sidel. (Photo: Sidel)

At the Interpack show in Germany next month, Sidel will unveil the new generation of its Cermex ProSelex flexible collating system for complex, unstable bottles. This gentle, streamlined grouping device is designed to work with any type of case packer. Acting as an integrated module of a case packer that is receiving products upstream from a single lane, this device continuously pitches, collates and prepares the container batches before they are transferred and case packed. The newest version boasts higher speeds as fast as 300 bottles/min and a smaller footprint. It also offers simpler and faster changeovers, from 1 min for a new collation to 2.5 min for a complete bottle change. A small number of change parts is needed to adapt the system to a new bottle format.

According to Sidel, the system is a response to proliferation of customized bottle designs in creative shapes that add brand identification but lead to challenges in conveying and handling. Servo-driven gentle handling and continuous flow are said to prevent shocks and scratches to bottles, as well as product jamming and “shingling.”

Related Content

-

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

-

First Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

-

US Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.