Tunnel Gate Inserts Gain U.S. Distributor

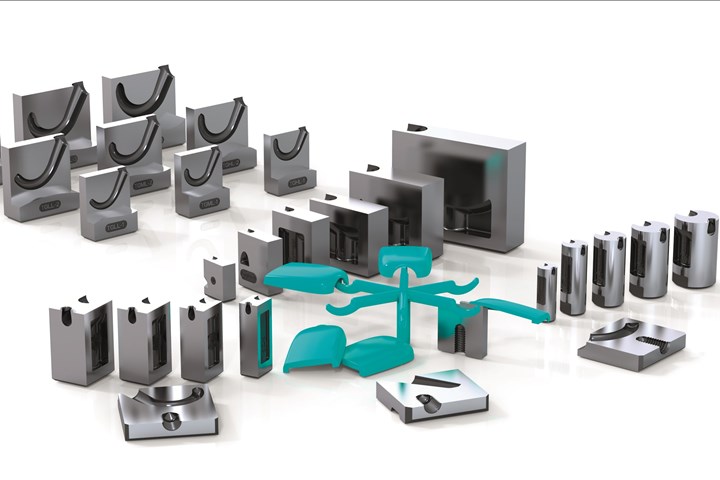

Distributed by PCS Company, i-mold’s tunnel gate inserts allow automatic degating of parts from the runner system during ejection and can hide gate marks on a part’s underside.

PCS Company is now distributing tunnel gate inserts in the U.S. from Erbach, Germany-based i-mold Molding Innovations. Founded in 2004, i-mold’s focus is on tunnel gate technology and demolding. Developed and produced in-house at i-mold, PCS says the tunnel gate inserts can provide high savings potential for moldmakers and injection molders by eliminating secondary operations or other means of degating.

Made via metal injection molding, i-mold says the dimensions of its tunnel gate inserts remain consistent from component to component.

Photo Credit: PCS Company

Also known as ‘cashew’ or ‘banana’ gate inserts, the tunnel gate inserts allow automatic degating of parts from the runner during ejection, and they can also can be used to hide gate marks on the underside of the molded part.

Made of M2 tool steel using metal injection molding (MIM), PCS says the i-mold inserts feature smooth feed channels and precise gate sizes that are repeatable from insert to insert. PCS adds that the inserts are suitable for all plastics thanks to their optimized feed channel geometry, including the ability to work with up to 60% filled materials.

Related Content

-

How 3D Printing Supports Toolmaking Workforce at This Multiscale Molder

At more than a century old, General Pattern has seen multiple evolutions in its 大象传媒 — the latest of which is the embrace of additive manufacturing technologies for mold tooling and beyond.

-

American Injection Molding Institute Opens Mold Maintenance Classroom

The Beaumont subsidiary has opened the Mold Maintenance Center of Excellence classroom at its Erie, Pennsylvania, headquarters.

-

AIM Institute Continues to Grow Plastics Education and Training on 10th Anniversary

The AIM institute was created in response to the rising need for skilled injection molding professionals, providing individuals with a fundamental understanding of plastic rheology and plastic flow through a mold.