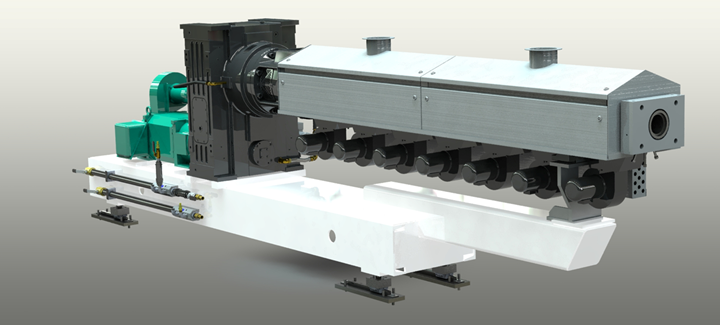

Sleek Extruder for Coating Applications

Smaller footprint, lighter weight allows machine to be readily integrated into existing carriages or platforms.

Davis-Standard has introduced a compact extruder engineered for extrusion coating applications. Called the CHP, the machine has a sleek design that provides a smaller footprint. It’s also said to be lighter in weight than comparably sized machines, allowing it to be more easily added to an existing carriage or platform structure. This provides processors with a space-saving replacement or coextrusion addition for increasing outputs and line speed.

The design addresses profitability factors such as reduced raw material loss, improved outputs, and greater application development, Davis-Standard says. It is built for exceptional performance with improved transition times and significantly higher processing rates than conventional extruders.

The CHP is available in sizes ranging from 2 in. to 4 in. (52 mm to 100 mm). Processors benefit from efficient mixing that delivers low pressure and melt temperature variability and output rates up to 80 to100% higher than current extruder options.

In addition, a reduced residence time of 3:1 with a faster purge between resins and colors supports quick changeovers minimizing raw material loss for bottom-line impact. Davis-Standard has a CHP extruder at its laboratory facility in Pawcatuck, Conn., for customers to run trials and validate processing opportunities prior to purchase.

Related Content

-

Roll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

-

How to Select the Right Tooling for Pipe Extrusion

In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative factors. Here’s some guidance to help you out.

-

What to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.