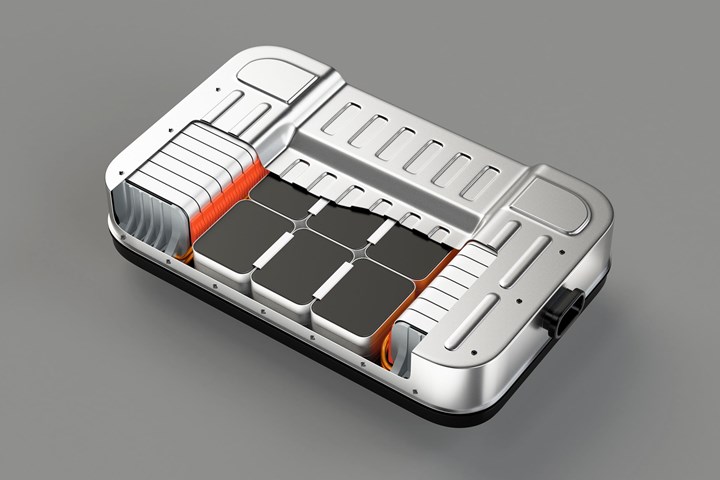

Renewable PVDF Grades for Lithium-Ion Batteries

Arkema develops new sustainable Kynar PVDF grades based on 100% renewable attributed carbon derived from crude tall oil.

A new range of renewable PVDF grades for lithium-ion batteries has been developed by Arkema. The sustainable Kynar CTO PVDF grades will claim 100% renewable attributed carbon derived from crude tall oil biofeedstock, according to a mass balance approach. Using the mass balance approach under the ISCC+ certification process, Kynar CTO grades will be first produced in Arkema’s Pierre-Bénite plant in France for its European customers, focusing initially on grades specifically targeted for the lithium-ion battery market.

This patent-pending technology reportedly allows a climate change impact reduction of almost 20% of the Kynar PVDF binder (expressed in kg eq. CO2/kg, according to the ISO14040 standard) while reducing dependence on upstream crude oil consumption. The crude tall oil used in upstream feedstock production is a residue of the Kraft process of wood pulp manufacture. The new CTO PVDF grades are certified to be compliant with industry leading responsible forestry standards. They do not result in deforestation, and there is no direct competition with food crops.

Said Anthony Bonnet, global R&D director for fluoropolymers, “Arkema has been a leader in advanced bio-circular polymers for many years. “Now, we are taking a huge step forward to make fluoropolymer grades using biosourced carbon only. It’s a remarkable innovation that we proudly share with our customers across the world. There is a real demand for more sustainable solutions and we are happy to play a leading role.”

In a second phase, the production of this range of sustainable PVDF grades will be extended to each of Arkema’s global PVDF manufacturing sites and will be made available to all traditional PVDF markets and applications. Furthermore, Arkema has already announced a project in the U.S. to produce PVDF grades using fluorine derived as a byproduct from the agrochemical industry, thus requiring no dedicated fluorspar mining. These grades are expected to be commercialized by mid-2022. Kynar CTO grades will be offered as functionally identical alternatives to Arkema’s flagship binder grades, Kynar HSV900 and Kynar HSV1810.

Related Content

-

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

-

Extrusion Technology Extended to Injection, Enabling Up to 100% Regrind Usage

Twin-barrel (shot-pot) press can handle more regrind, offers other benefits to molders.

-

Shredding Thin Film: How to Do It Right

While many processors recoil at this task, a little know-how in shredding equipment, processing, and maintenance should add the necessary confidence.