Offline, Automated Inspection and Analysis Tool for Plastics

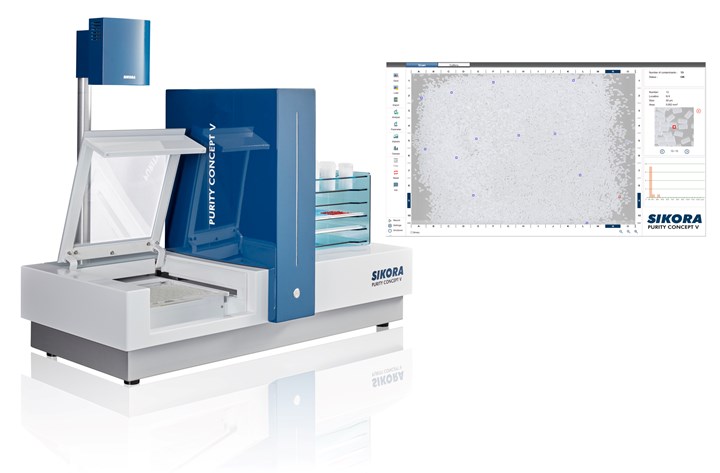

Sikora’s Purity Concept V reportedly combines the functionality of an optical light table with an automatic evaluation, said to be unique to the market.

A new offline, automated purity inspection and analysis tool for plastic raw materials that reportedly combines the functionality of a conventional optical light table with an automatic evaluation is being showcased at this month’s PTXPO by Sikora International. Said to be unique to the market, Purity Concept V is designed for laboratory testing or random sample inspection which can be done on various forms of plastic material: pellets, flakes, and testing plates.

The automated light table inspects the test material placed on a sample carrier and evaluates the image recordings quickly and accurately. Individual contaminants such as black specks and color deviations down to 50 µm are detected and highlighted on the monitor and marked optically on the sample carrier, thus allowing for a clear visual of the physical contamination. Follow-up controls of past inspections and analysis are possible at any time.

Related Content

-

Upgraded CT Scanning and Multi-Sensor Coordinate Measuring Machines

Werth’s TomoScope S Plus 240 systems boast more than double the measuring volume as their predecessor with almost the same size.

-

SPE Thermoforming Division Announces Biennial Parts Competition Call for Entries

This year’s parts competition includes two new categories with a focus in innovations in the use of sustainable thermoforming and in applications for electric vehicles and batteries.

-

Measuring Technology Specialist Pixargus Acquired by CiTex Group

A global player in optical inline quality control, Pixargus is intensifying presence in U.S. & Asia under CiTex umbrella.