Software Guides 3D Print Settings Independently of Use Case

New software feature in Eiger predicts additive manufactured part performance.

offers a new feature, Performance Advisor, for its Eiger 3D print management software, which will evaluate part performance characteristics without the need to define a specific use case.

Print settings configured in Eiger can influence the strength and performance of the final printed part. Some settings are more impactful than others. For example, adding continuous fiber reinforcement clearly will increase strength, but the impact of adding a wall layer or adjusting fill density is less obvious. Also, trade-offs between strength and material cost and print time are important considerations. Ideal print settings will result in a strong part that is manufactured efficiently.

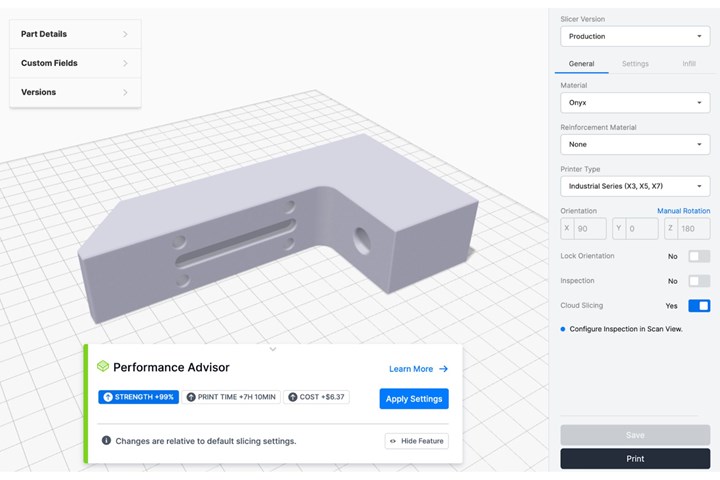

Screenshot of part simulation using Performance Advisor. Source: Markforged

Markforged customers use the existing Simulation tool to explore how changes in print settings impact part performance, and optimize for cost and print time. However, Simulation requires a known use case — how the part will be loaded and how it interacts with other objects when it is in service — which is often unknown.

The Performance Advisor tool was developed to address this, using analysis of part performance to recommend print settings that make parts stronger by a known quantity, while keeping added cost and time to a minimum.

The tool is fully automated, no user input is needed to generate the results. After a part is saved in Eiger, Performance Advisor will automatically analyze it and recommend print settings that, relative to the default settings, improve the strength while keeping material cost and print time low. The user will then decide if the performance improvement is worth the added cost and print time. Recommended settings can be applied with one-click or ignored before proceeding with the Eiger workflow.

Markforged has developed a physics-based analysis method to address the challenge of doing structural analysis without a use case. According to Markforged, the shapes in which a part geometry naturally vibrate are used to explore the impact of print settings. These eigenmodes are used to identify the regions of the part most susceptible to deformation and stress, and suggest ways of making those regions stronger.

The initial release of Performance Advisor supports only Markforged Onyx material; adjusts only the settings for wall, roof and floor layers; and the fill pattern is limited to triangular. Markforged says the capabilities of Performance Advisor will grow with time.

Related Content

-

420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's additive manufacturing technology is designed for precision tooling.

-

KraussMaffei Nears Completion of Corporate Headquarters Move

The 185-yr old German maker of plastics processing machinery is shifting to a more than 200,000-m2 greenfield site in Parsdorf.

-

How 3D Printing Supports Toolmaking Workforce at This Multiscale Molder

At more than a century old, General Pattern has seen multiple evolutions in its 大象传媒 — the latest of which is the embrace of additive manufacturing technologies for mold tooling and beyond.