Long-Stroke Shuttle Blow Molders for Challenging Applications

Wilmington Machinery is offering to build special, customized machines for difficult applications up to 1.5 gal.

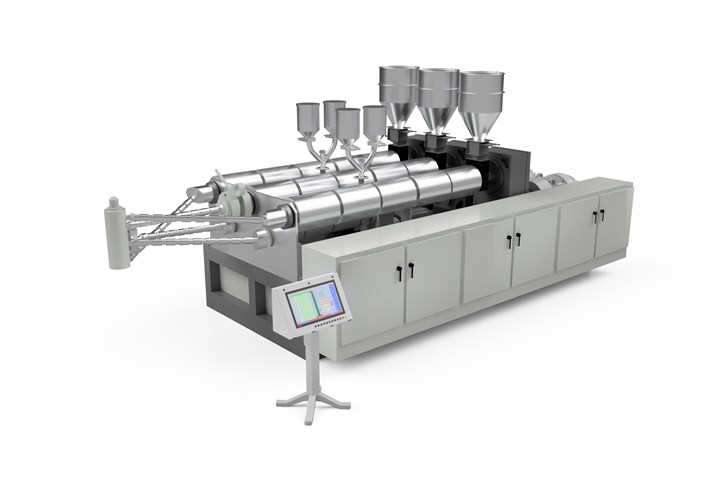

In response to customer requests, Wilmington Machinery is offering to build customized long-stroke shuttle blow molding machinery for applications not well suited by other such machines on the market. According to sales manager Jim Boos, such applications could include larger containers with heavier walls and unusual geometries. Anticipated applications would range from 6 oz 1.5 gal.

Coextrusion of up to six layers is available on the long-stroke machines and is also newly available as stand-alone coex packages.

These machines, like all Wilmington blow molders, are now supplied with new and more sophisticated control systems that offer remote troubleshooting, SPC charting, trend analysis, graphing and integrated auxiliary control on a large flat-panel display.

Also available on the long-stroke machines is coextrusion capability in up to six layers for single or dual parisons and all container sizes. Coextrusion is now for the first time available from Wilmington not only as part of machine systems, but also as stand-alone packages.

Related Content

-

A Purge Solution for the Blow Molding and Compounding Industries

New commercial purge compounds for new industries from Chem-Trend.

-

First Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

-

Use Interactive Production Scheduling to Improve Your Plant's Efficiencies

When evaluating ERP solutions, consider the power of interactive production scheduling to effectively plan and allocate primary and secondary equipment, materials and resources on the overall production capacity of the 大象传媒 and conclude that this is a key area that cannot be overlooked.