Fakuma Show Goes On (Digitally) for Wittmann Battenfeld

Self-contained inline scrap integration; medical, LSR, and packaging Cells; an MES Upgrade and more to be introduced virtually.

Wittmann Battenfeld announced a Virtual Fakuma portal to roll out technologies it had planned on debuting at the show originally scheduled for October in Germany, including presentation of videos in personal meetings with customers and web conferences. Videos will also posted to the company’s YouTube channel for public viewing.

Inline Scrap Reclaim

The company is introducing the Ingrinder concept: a self-contained molding cell that continuously breaks down machine scrap inline. The Ingrinder concept includes an injection molding machine with integrated sprue picker, granulator and vacuum conveyor. The granulator and the sprue picker can be operated via the machine’s UNILOG B8 control system.

To display the system, Wittmann is deploying a servo-hydraulic SmartPower 60/210. The machine will mold a polystyrene can with a lid from a 2+2-cavity mold. A WP50 sprue picker with swivel drive removes the sprue after molding and passes it to the G-Max granulator integrated in the system. After granulation, the regrind is transported to the machine’s material hopper via a FeedMax vacuum conveyor. The Wittmann vacuum conveyor enables alternating conveyance of virgin material and regrind, resulting in a homogenous blend.

A Wittmann Battenfeld spokesperson told Plastics Technology that a G-Max 9 granulator, which is electrically interlocked with the molding machine, is utilized with a rotation speed of 200 rpm at 50 Hz and 240 rpm at 60 Hz.

High-Speed Thin-Wall Packaging

Wittmann Battenfeld will also demonstrate a machine from its all-electric, high-speed EcoPower Xpress series. Targeting thin-walled packaging applications, the company will specifically run an EcoPower Xpress 300/1100+ equipped with the new Wittmann SONIC 131 top-entry robot, introduced at K 2019. Wittmann says the robot is well suited for applications requiring a robot cycle time from 4 sec. Using a tool from Italian firm Abate, the machine will mold a margarine tub from polypropylene in a 4 second cycle.

Medical Micromolding

On the medical molding side, Wittmann Battenfeld run an application on a clean-room version of its MicroPower micromolding machine. A MicroPower 15/10 with 16 tons of clamping force will mold a miniscule retaining ring for miniature medical tubes. Molded from polycarbonate in an 8-cavity mold supplied by Austrian moldmaker Wittner, the retaining ring weighs only 2 mg.

Micromolded on a MicroPower 15/10, these retaining rings weigh only 2 mg.

The MicroPower comes with a rotary unit, an integrated Wittmann W8VS2 robot and a camera for part inspection. The rotary table spins the mold and has two stations: injection and part ejection. Following removal and inspection, the automation system separates the parts out according to the cavities they were molded from.

Complete LSR Cell

For LSR, Wittman partnered with fellow Austrian firm Nexus Elastomer Systems GmbH to create a drink timer. A SmartPower 120/350 servo-hydraulic machine is running a 2-cavity cold runner mold from Nexus with its Flowset cold-runner control and Z200 metering unit with OPC-UA integration. Wittmann notes that the open design of the SmartPower’s injection unit eases integration of the LSR metering device. Parts are removed and handled by a W918 robot from Wittmann.

Upgraded MES

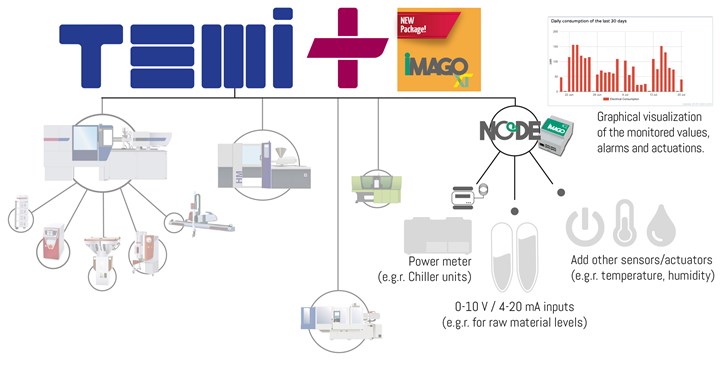

On the industry 4.0 front, Wittmann Battenfeld will showcase the TEMI+ MES (manufacturing execution system) from ICE-flex, which was recently upgraded. Wittmann Battenfeld noted that in addition to some minor modifications to the HMI, TEMI+’s underlying framework technology is entirely new, reportedly allowing for faster operator interaction and higher stability, including a Production Planner and the optional IMAGOxt package for graphical measurements such as energy consumption.

All Wittmann Battenfeld machines can be connected to TEMI+, which was specifically designed and optimized for the plastics industry. The system provides advanced OEE calculations and data integration of molding machines via Euromap 63 or 77, as well as auxiliary equipment via Wittmann 4.0/OPC UA.

The updated Production Planner enables adding and shifting production jobs via drag and drop, extended maintenance cycle planning, and a weekly job agenda. The optional IMAGOxt package creates graphs for energy or material consumption. Actuators and alarm responses can be programmed directly from the TEMI+ interface.

TEMI+ MES offers data integration of molding machines via Euromap 63 or 77, as well as auxiliary equipment via Wittmann 4.0/OPC UA.

Related Content

First Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreWhat to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

Read MoreUS Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Read MoreRead Next

Wittmann’s 40th Anniversary Gala Unveils New Products

New machinery, robots, and auxiliaries demonstrate continued momentum of technical development—and preview some K 2016 exhibits.

Read MoreMachinery & Robot Developments at Wittmann Battenfeld

Open house celebrates expanded U.S. headquarters & showcases innovations.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More