Direct Gating of In-Mold Decorated Parts

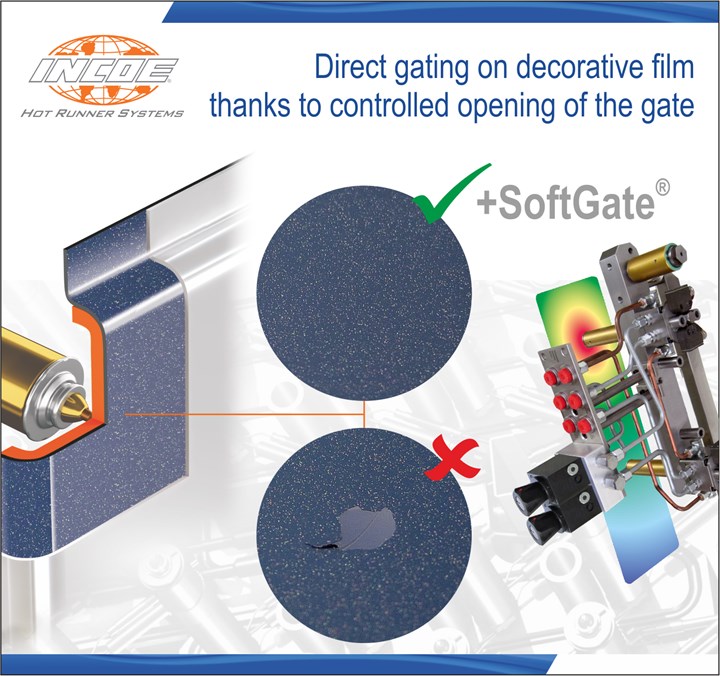

Incoe’s SoftGate Velocity VG pin control technology allows direct valve gating of parts with an over-molding film or fabric.

Share

In mold decorating (IMD) involving the over-molding of film or fabric and utilizing direct valve gating typically results in the “blast” of the plastic in the gate area damaging the film or wrinkling the fabric. To combat this, Incoe (Auburn Hills, Mich.) introduced its SoftGate Velocity VG pin control technology, which allows these types of applications to be direct gated without surface blemishes. Specifically, SoftGate allows the melt to stream over the decorative film without damaging it. This technology will be on display at the (March 29-31; Donald E. Stephens Convention Center; Rosemont, Ill.)

The impact caused by melt flowing abruptly into the cavity after the valve gate nozzle has been opened conventionally can be seen in the image detail.

Photo Credit: Incoe

Related Content

-

Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

-

RFID Applied to Hot Runner Systems

Hasco says the adapted variant of the Mold Tag makes it possible to read out all data on the hot half or a wired system directly on a smartphone.

-

Integrated RFID Technology Offers Smart Connectivity for Hot Runner Systems

Intelligent tool networking with integrated radio frequency identification (RFID) technology maximizes toolmaking efficiencies with seamless mold identification, instant access to critical data and streamlined spare part ordering.