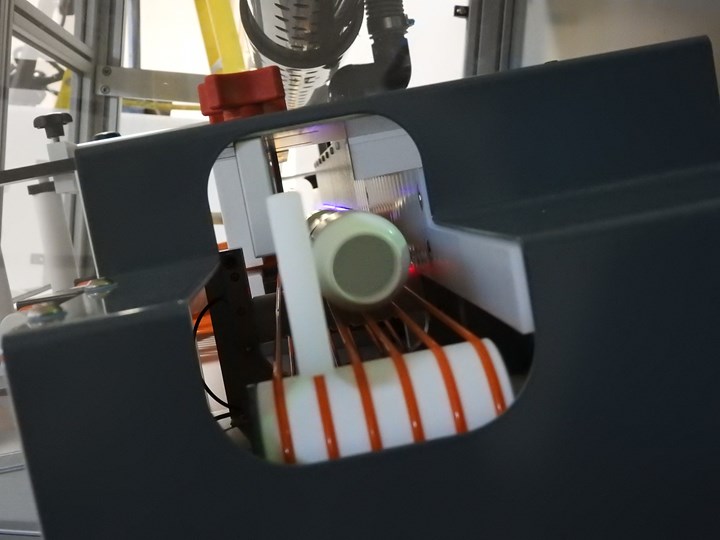

Corona Treatment System for Improved Decoration of Bottles

3DT’s new and versatile BottleDyne quickly treats bottles for better adhesion.

A corona treatment system newly engineered for improving adhesion on cylindrical plastic bottles has been launched by 3DT, Germantown, Wisc. The fully-integrated BottleDyne system is said to invisibly alter surfaces for the improved bonding of ink, adhesives, and labels for decorating applications.

This versatile system reportedly treats thousands of bottles per hour quickly and efficiently and is engineered to easily adjust for varying bottle sizes. It is equipped with Allen Bradley control systems providing numerous treatment options and real-time insight on performance. With 30 years in the production of corona treating systems, customers will find that 3DT’s BottleDyne has been designed with the wise and thoughtful engineering needed to assure powerful adhesion and non-stop production. Said to use little energy and to require very minimal maintenance, BottleDyne’s other key features include:

â–ª Compact floor model designed to easily integrate into molding, labeling and printing lines or used as a stand-alone work station.

â–ª Fast line speed; capable of treating 3,000 bottles per hour.

â–ª Flexible in accommodating a broad range of bottle sizes from 1¼ in. to 3 in. in diameter and up to 12 in. tall.

â–ª Bottles are treated in a single lane as they ride and rotate 360 degrees through the corona treating station. A variable speed belt system delivers the bottles.

â–ª Powerful corona discharge raises dyne levels on the plastic materials (PP, HDPE, L/LDPE, and PET) to at least 42 dynes/cm creating the secure bond of inks, adhesives, and labels.

â–ª Equipped with an ozone destruction system to meet EPA requirements.

â–ª Supplied with 3DT’s powerful PolyDyne corona generator and transformer.

â–ª Control system is operated by Allen-Bradley’s Micrologix PLC for local or remote treatment and operation. Other control features include: AB PanelView Plus to set speed and power, alert for lane jam, corona output indicator, and other performance data.

Related Content

-

ColorForm From KraussMaffei Brings Key Competencies to One System

ColorForm systems produce finished injection-molded parts with a flood-coating, scratch and UV resistant finish.

-

Athena Controls Emphasizes Customization: Buy Just What You Need

At NPE, 60-year-old Athena reintroduces itself as a vendor of standard control platforms customized for maximum utility and economy.

-

Transforming Laser Marking Operations With Collaborative Robotic Automation

FOBA partners with Flexxbotics and Universal Robots.