Cobot Takeout System for Shuttle Machines

NPE2024: Proco Machinery upgrades its Robopik bottle takeout system for shuttle blow molders with the addition of a collaborative robot.

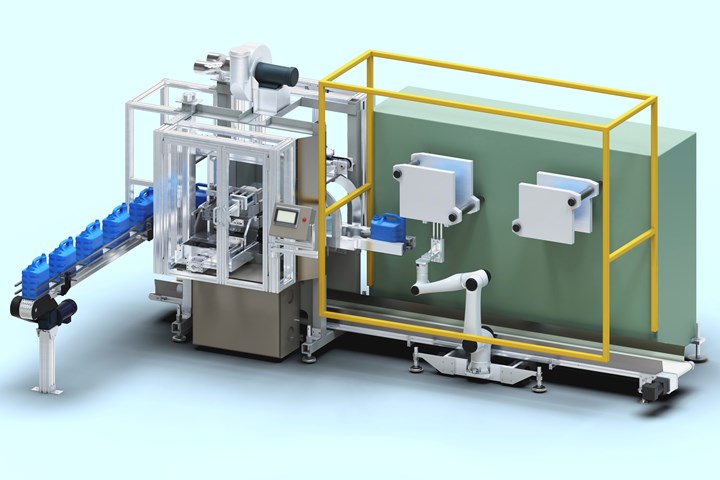

Updated Robopik bottle takeout system from Proco Machinery substitutes a versatile cobot for older fixed automation. Source: Proco Machinery

The next generation of Proco Machinery’s Robopik bottle takeout system is distinguished by its use of a jointed-arm collaborative robot (cobot), said to offer greater flexibility and adaptability than older fixed automation. The Robopik, designed for unloading and deflashing containers from shuttle blow molders, can be reconfigured easily to handle different types of products and adapt to changing production requirements, Proco says. The magnetically coupled cobot is said to also unload products faster and with greater accuracy than previous systems. The new system can handle delicate or irregularly shaped containers and minimize the risk of damage or defects.

It also features built-in safety features such as collision detection, emergency stop mechanism and protective barriers. Advanced connectivity enables seamless integration with other “smart factory” (Industry 4.0) technologies.

Related Content

-

Real-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

-

AI: The Next Big Thing in Plastics Processing

Discover how artifical intelligence is revolutionizing plastics processing. Hear from industry experts on the future impact of AI on your operations and envision a fully interconnected plant.

-

ICIS Launches: Ask ICIS Generative AI Commodities Assistant

Said to be the first of its kind, this AI assistant will enhance access to ICIS’ intelligence and insights for the energy and chemical markets.