Cobot Case Packer for Containers

Compact, mobile system with collaborative robot eases labor shortage for container packing.

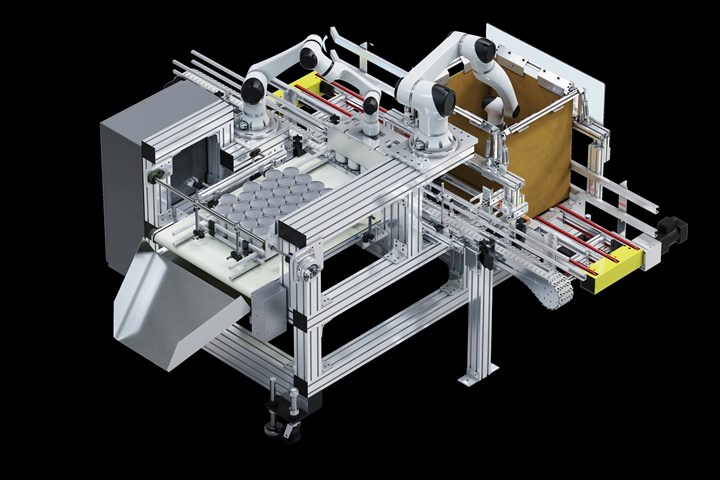

Integrated system includes accumulator, pick-and-place cobot, automatic box infeed and exit conveyor. (Photo: Proco Machinery Inc.)

A solution to labor shortages among packaging producers is offered by Proco Machinery Inc. in the form of the new Collaborative Robot Packer. This compact integrated system is highly flexible for handling a variety of rigid container shapes and sizes. Mounted on casters, the modular system includes a collating accumulation system with built-in bottle pusher, jointed-arm collaborative robot (cobot), automatic box infeed conveyor, automatic box exit conveyor and poly-bag vacuum feature.

The cobot is available in different models. It works alongside operators and is easy to teach for precise positioning of containers in different patterns and layers. Proco supplies end-of-arm tooling. The overall system boasts low capital cost, simple design with minimal moving parts, minimal setup, low maintenance and one-year payback, according to Proco. Large touchscreen controller can store up to 25 job recipes, such as all necks up, all necks down, or alternating rows of each.

Related Content

-

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

-

Impacts of Auto’s Switch to Sustainability

Of all the trends you can see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

-

PHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.